- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 12, 2024 11:19 Back to list

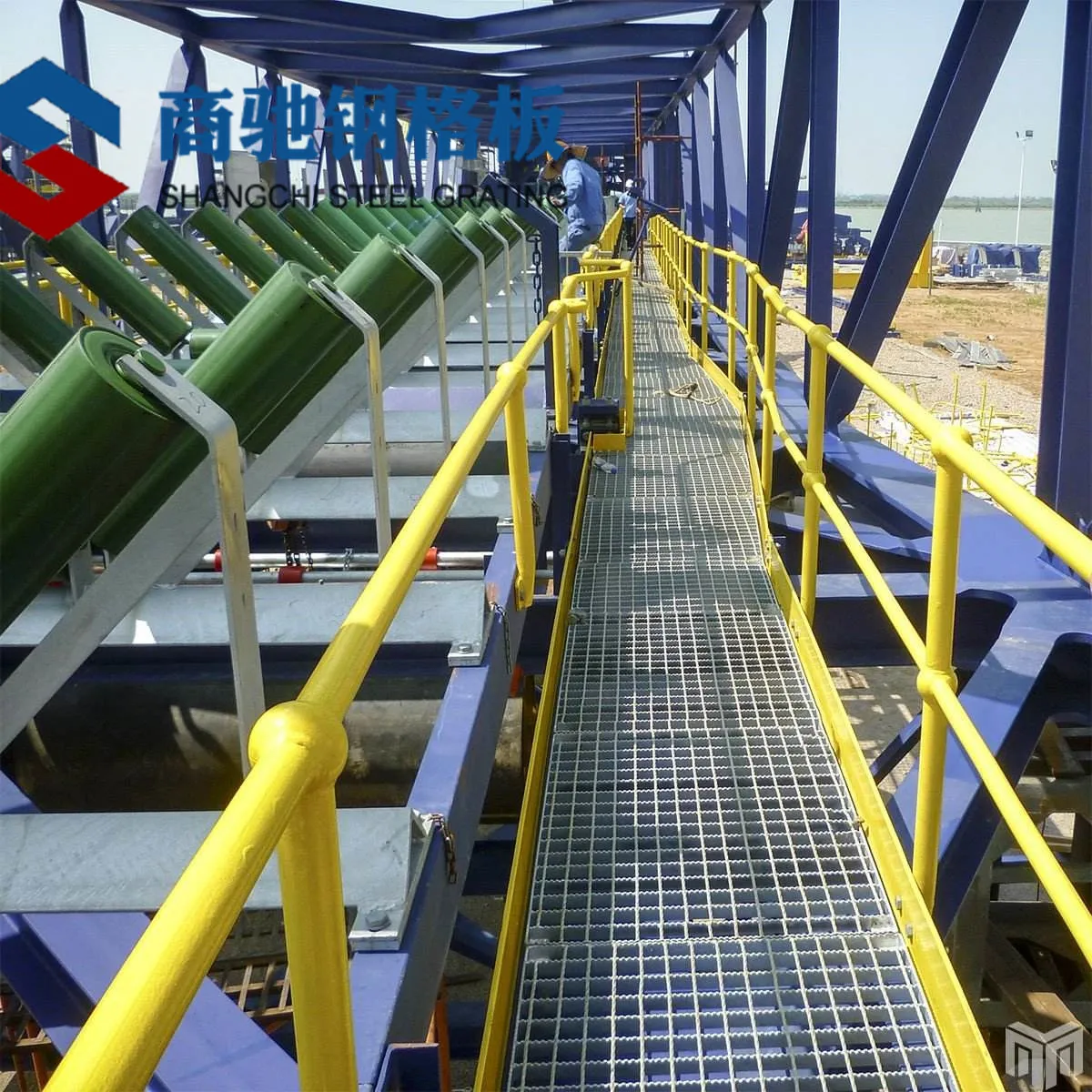

The Benefits and Uses of Hot-Dip Galvanized Grating in Different Industries

Hot-dip galvanized grating is a type of steel grating that has been coated with zinc through a hot-dip galvanizing process. This process involves immersing the steel grating in a molten bath of zinc, which reacts with the steel to form a protective layer that enhances its corrosion resistance and durability.

Benefits of Hot-Dip Galvanized Grating

There are several benefits to using hot-dip galvanized grating in various industries:

Corrosion Resistance: The zinc coating provides excellent protection against rust and corrosion, extending the lifespan of the grating.

High Strength: The grid structure of hot-dip galvanized grating offers high load-bearing capacity, making it suitable for heavy-duty applications.

Lightweight and Easy to Install: The lightweight nature of hot-dip galvanized grating makes it easy to handle and install, reducing labor costs and installation time.

Durable and Long-lasting: With proper maintenance, hot-dip galvanized grating can last for many years, providing a cost-effective solution for various applications.

Aesthetic Appeal: The sleek and modern appearance of hot-dip galvanized grating enhances the aesthetic appeal of any project.

Uses of Hot-Dip Galvanized Grating in Different Industries

Hot-dip galvanized grating is widely used in various industries due to its combination of benefits. Here are some examples of its applications:

Petrochemical Industry: In refineries and chemical plants, hot-dip galvanized grating is used for platforms, walkways, and trench covers. Its corrosion resistance and high strength make it ideal for these harsh environments.

Power Plants: Hot-dip galvanized grating is used for floors, walkways, and safety barriers in power plants. Its durability and lightweight nature make it easy to install and maintain.

Water and Wastewater Treatment Plants: In water and wastewater treatment plants, hot-dip galvanized grating is used for covers, walkways, and drainage systems. Its corrosion resistance ensures that it can withstand the harsh chemicals and environments found in these facilities.

Municipal Engineering: Hot-dip galvanized grating is used for sidewalks, parking garages, and public buildings in municipal engineering projects. Its sleek appearance and durability make it an ideal choice for these applications.

Environmental Engineering: In environmental engineering projects, hot-dip galvanized grating is used for retaining walls, slope protection, and erosion control. Its high strength and corrosion resistance make it suitable for these demanding applications.

Customization Options for Hot-Dip Galvanized Grating

Hot-dip galvanized grating can be customized to meet the specific needs of any project. Options include different sizes, shapes, and materials, as well as various surface treatments such as painting or additional galvanizing. This flexibility allows hot-dip galvanized grating to be used in a wide range of applications and environments.

In conclusion, hot-dip galvanized grating is a versatile and durable building material that offers numerous benefits to various industries. Its corrosion resistance, high strength, lightweight nature, durability, and aesthetic appeal make it an ideal choice for a wide range of applications. With its ability to be customized to meet specific needs, hot-dip galvanized grating is a valuable addition to any project in the petrochemical, power, water, municipal engineering, and environmental engineering industries.

As a specially in metal wire mesh products , our business scope is very broad .We have galvanized expanded metal mesh, fiberglass insect screen , hot dip galvanized grating, concertina wire , galvanized razor wire, hot dipped galvanized fence, galvanized welded wire mesh and hexagonal gabion mesh and so on . The hot dip galvanized grating price in our company are reasonable . If you are interesting in our product welcome to contact us !

-

Durable River Bank Gabion Mesh Solutions for Protection

NewsNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

NewsNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

NewsNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

NewsNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

NewsNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

NewsNov.17,2025