Velkommen til våre nettsider!

- afrikansk

- albansk

- amharisk

- arabisk

- armensk

- aserbajdsjansk

- baskisk

- hviterussisk

- bengali

- bosnisk

- Bulgarsk

- katalansk

- Cebuano

- Kina

- Kina (Taiwan)

- korsikansk

- Kroatisk

- tsjekkisk

- dansk

- nederlandsk

- Engelsk

- Esperanto

- estisk

- finsk

- fransk

- frisisk

- galisisk

- georgisk

- tysk

- gresk

- Gujarati

- haitisk kreolsk

- hausa

- hawaiisk

- Hebraisk

- Nei

- Miao

- ungarsk

- islandsk

- igbo

- indonesisk

- irsk

- italiensk

- japansk

- javanesisk

- Kannada

- kasakhisk

- Khmer

- rwandisk

- koreansk

- kurdisk

- kirgisisk

- Arbeid

- latin

- latvisk

- litauisk

- luxemburgsk

- makedonsk

- Malgashi

- malaysisk

- Malayalam

- maltesisk

- Maori

- Marathi

- mongolsk

- Myanmar

- nepalesisk

- norsk

- norsk

- oksitansk

- Pashto

- persisk

- Pusse

- portugisisk

- Punjabi

- rumensk

- russisk

- samoansk

- skotsk gælisk

- serbisk

- Engelsk

- Shona

- Sindhi

- singalesisk

- slovakisk

- slovensk

- Somali

- spansk

- Sundanesisk

- Swahili

- svensk

- Tagalog

- tadsjikisk

- Tamil

- tatarisk

- Telugu

- Thai

- tyrkisk

- turkmenske

- ukrainsk

- Urdu

- Uigur

- usbekisk

- vietnamesisk

- walisisk

- Hjelp

- Jiddisch

- Yoruba

- Zulu

sep . 15, 2025 10:53 Tilbake til listen

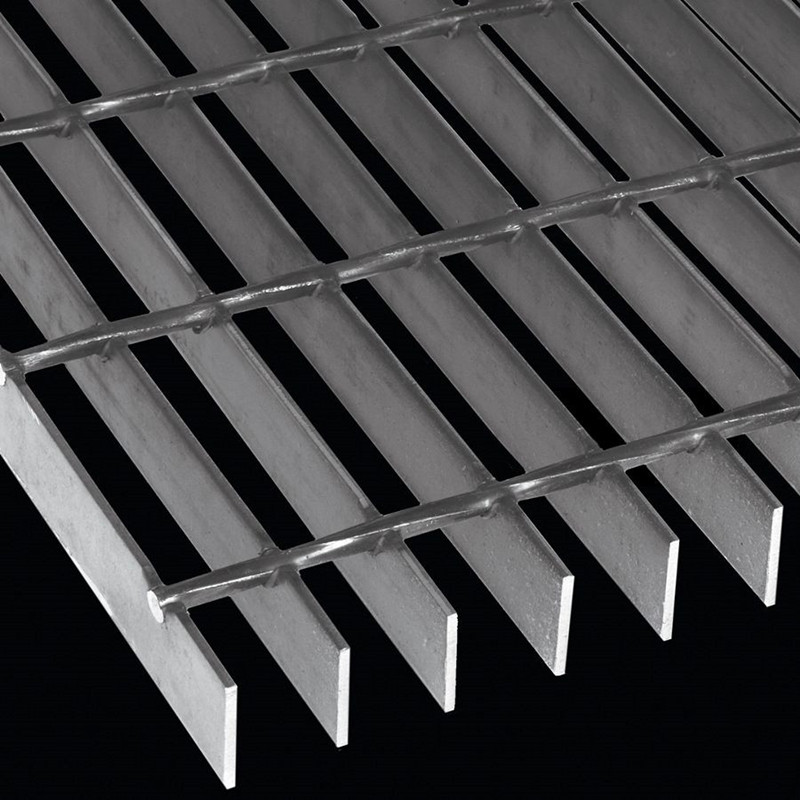

Hot Dipped Galvanized Steel Grating | Durable & Anti-Corrosion

Varmgalvanisert stålrist/stangrist is a key solution in the manufacturing industry, specifically within Fabricated metal products and Metal structure manufacturing. This article explores how Anping County Xingzhi Metal Wiremesh Products Co.,Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Hot Dipped Galvanized Steel Grating/Bar Grating Overview

- Benefits & Use Cases of Hot Dipped Galvanized Steel Grating/Bar Grating in Metal structure manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Hot Dipped Galvanized Steel Grating/Bar Grating from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

Hot Dipped Galvanized Steel Grating/Bar Grating Overview

In the demanding world of manufacturing, especially within Fabricated metal products and Metal structure manufacturing, the choice of materials directly impacts safety, longevity, and operational efficiency. Here, Varmgalvanisert stålrist/stangrist stands out as an indispensable component. This robust product consists of bearing bars and cross bars, typically resistance-welded, mechanically locked, or press-locked, forming an open-grid panel. The defining characteristic is the hot-dipped galvanization process, where fabricated steel is immersed in a bath of molten zinc. This creates a metallurgical bond and a durable, corrosion-resistant coating that far surpasses the protection offered by paint or other surface treatments. Its relevance across manufacturing is profound, providing superior load-bearing capabilities, excellent slip resistance, and optimal drainage in various industrial settings. From walkways and platforms to trench covers and mezzanines, the inherent strength and open design of steel grating make it ideal for environments where safety, ventilation, and light penetration are critical. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd is a trusted name in this specialized field, known for manufacturing high-quality Hot Dipped Galvanized Steel Grating/Bar Grating that meets stringent industry standards and client specifications, ensuring reliability and performance for every project.Benefits & Use Cases of Hot Dipped Galvanized Steel Grating/Bar Grating in Metal structure manufacturing

Within Metal structure manufacturing, the applications for Hot Dipped Galvanized Steel Grating/Bar Grating are extensive and critical. Its unique properties make it ideal for numerous structural and access solutions. For instance, it's widely used for industrial platforms, providing safe and stable working surfaces for personnel and equipment. Walkways, stair treads, and catwalks benefit immensely from its slip-resistant surface and high load-bearing capacity, which are vital for safety in busy industrial environments. Trench covers and drainage systems also frequently utilize this grating, as its open design allows for effective fluid and debris management while maintaining structural integrity. The competitive advantages of Hot Dipped Galvanized Steel Grating/Bar Grating, particularly from a specialist like Anping County Xingzhi Metal Wiremesh Products Co.,Ltd, are clear. The hot-dipped galvanization process ensures exceptional resistance to rust and corrosion, significantly extending the product's lifespan even in harsh chemical or outdoor conditions. This translates into minimal maintenance requirements and reduced replacement costs over time. Furthermore, the high strength-to-weight ratio allows for efficient designs without compromising structural integrity. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd leverages its deep expertise in this sector, providing tailor-made solutions that integrate seamlessly into complex metal structures, delivering both functionality and long-term value.Cost, Maintenance & User Experience

Investing in Hot Dipped Galvanized Steel Grating/Bar Grating from a reputable supplier like Anping County Xingzhi Metal Wiremesh Products Co.,Ltd represents a shrewd long-term financial decision for businesses in the Fabricated metal products sector. While the initial investment might be higher than some alternative materials, the total cost of ownership (TCO) proves significantly lower. The primary driver of this superior ROI is the exceptional durability conferred by the hot-dip galvanization process. This protective zinc coating is metallurgically bonded to the steel, offering unparalleled resistance against corrosion, abrasion, and impact damage. This means fewer replacements, minimal repairs, and a drastically reduced need for ongoing maintenance like painting or rust treatment. Customers in the Fabricated metal products sector frequently report high satisfaction with the longevity and consistent performance of Anping County Xingzhi Metal Wiremesh Products Co.,Ltd's Hot Dipped Galvanized Steel Grating/Bar Grating. Feedback often highlights the product’s ability to withstand harsh industrial environments, from chemical plants to offshore platforms, without degradation. The robust nature ensures a safer, more reliable working surface over decades, contributing positively to operational continuity and employee well-being. This superior user experience and low maintenance demand translate directly into substantial savings and peace of mind for B2B decision-makers.Sustainability & Market Trends in manufacturing

In today's manufacturing landscape, sustainability is no longer a niche concern but a core business imperative, particularly within the Fabricated metal products and Metal structure manufacturing sectors. Hot Dipped Galvanized Steel Grating/Bar Grating aligns perfectly with this trend due to its extended lifecycle and recyclability. The exceptional corrosion resistance significantly prolongs the useful life of the grating, reducing the frequency of replacement and, consequently, minimizing waste generation. Furthermore, steel itself is one of the most recycled materials globally, making Hot Dipped Galvanized Steel Grating/Bar Grating an environmentally responsible choice at the end of its long service life. Regulatory compliance and safety standards are also driving market trends, with a growing emphasis on durable, low-maintenance materials that ensure worker safety and structural integrity. The consistent quality and performance of products from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd not only meet but often exceed these stringent requirements. As global infrastructure development and industrial expansion continue, the demand for reliable, sustainable, and cost-effective structural components like Hot Dipped Galvanized Steel Grating/Bar Grating is set to grow. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd is positioned as a forward-thinking and eco-conscious partner, committed to supplying products that support both operational excellence and environmental stewardship.Conclusion on Hot Dipped Galvanized Steel Grating/Bar Grating from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

In conclusion, for B2B decision-makers in manufacturing, Fabricated metal products, and Metal structure manufacturing, Hot Dipped Galvanized Steel Grating/Bar Grating represents an indispensable investment. Its unparalleled durability, superior corrosion resistance, and robust load-bearing capabilities ensure long-term safety, efficiency, and significant cost savings through reduced maintenance and extended lifespan. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd stands as a testament to quality and reliability in this critical segment, providing expertly engineered Hot Dipped Galvanized Steel Grating/Bar Grating solutions that consistently exceed industry expectations. Partnering with us means choosing a product that enhances operational integrity, promotes safety, and supports your commitment to sustainability. Elevate your industrial infrastructure with the best in the business.- Contact us: email: sales2@xzmetal.com

- Visit our website: https://www.xzmetal.com

Dele

Siste nytt

-

Durable River Bank Gabion Mesh Solutions for Protection

NyheterNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

NyheterNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

NyheterNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

NyheterNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

NyheterNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

NyheterNov.17,2025