Nov . 06, 2025 10:10 Back to list

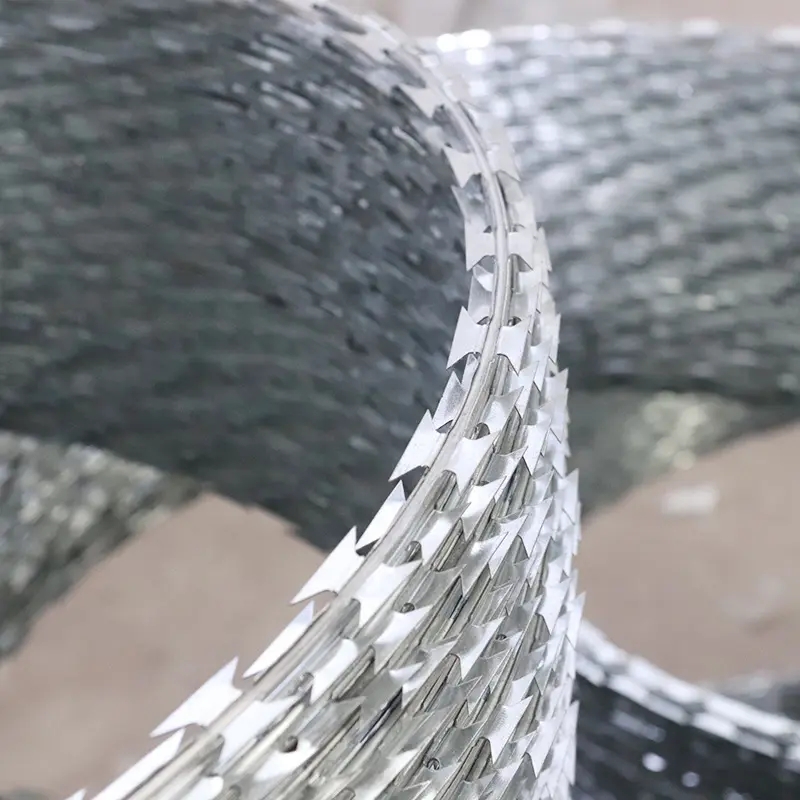

Single Loop Spiral Razor Barbed Wire Coil(Coin Type) HDG/SS

Field Notes on Single Loop Spiral Razor Barbed Wire Coil(Coin Type)

Security fencing rarely makes headlines—until it fails. Over the past year I’ve walked factory yards, farming perimeters, even a few remote telecom towers, and the pattern is clear: facilities are upgrading to coin-type single loop razor coils for fast deployment and visible deterrence. To be honest, the price/performance sweet spot is what’s moving the market.

What’s driving demand

- Insurance audits now push for visible perimeter upgrades (fewer claims, fewer headaches).

- Construction sites want rapid-install edge protection that crews can move week-to-week.

- Rural utilities—surprisingly—cite wildlife control as much as anti-intrusion.

In fact, many customers say the coin-type blade profile hits that “looks sharp, lasts long” spot without the maintenance of complicated concertina clips.

Core specifications (real-world ranges)

| Parameter | Typical Value | Notes |

|---|---|---|

| Core wire material | Q195 / Q235; optional SS304/SS316 | Carbon steel for cost-efficiency; stainless for harsh marine zones |

| Surface finish | Galvanized, Stainless, PVC coated | Zinc ≈ 60–275 g/m² (HDG); PVC ≈ 0.4–0.6 mm |

| Coil diameter | 450, 730, 980 mm (others on request) | General specs; custom sizes available |

| Blade (coin type) | Thickness ≈ 0.5 mm; spacing ≈ 26–30 mm | Real-world use may vary by site risk |

| Tensile strength | ≈ 350–550 MPa (core wire) | Balanced for formability and hold |

The Single Loop Spiral Razor Barbed Wire Coil(Coin Type) trades complexity for speed: no cross-clips, fewer accessories, quick tie-in to chain-link, palisade, or masonry crowns.

Process and quality checks

- Materials: Q195/Q235 cold-rolled wire; blades stamped from galvanized or stainless strip.

- Methods: continuous stamping (coin-type); spiral forming; spot-fix of blade to core; coil sizing.

- Coatings: HDG to ASTM A641/A641M; PVC adhesion per ASTM D3359 (≈ 4B–5B typical).

- Testing: zinc thickness gauges; salt spray per ISO 9227 (PVC/SS variants show >240 h; HDG varies by Zn mass).

- Service life (indicative): HDG ≈ 8–15 years; PVC ≈ 10–15; SS304/316 ≈ 15–25 (site climate matters).

Applications and advantages

- Perimeters: logistics yards, airports (non-airside), substations, farms, mines.

- Retrofit friendly: ties to existing mesh or wall capping quickly—actually a weekend job.

- Deterrence: high visual impact; coin profile resists casual cutting.

- Value: fewer clips, less labor, consistent coil geometry.

Vendor snapshot (field comparison)

| Vendor | Origin | Coatings | Certs | Lead Time | Notes |

|---|---|---|---|---|---|

| XZ Metal (manufacturer) | Anping, Hebei, China | Galv / SS / PVC | ISO, SGS | ≈ 7–15 days | Direct factory QC; custom sizes |

| Regional trader | Mixed | Mostly Galv | Varies | ≈ 10–25 days | Convenient, higher margin |

| OEM overseas | EU/SEA | SS / Specialty | ISO | ≈ 20–40 days | Premium pricing |

Customization, install, and a quick case

- Customization: coil diameter, blade pitch, PVC color (RAL), packing, labeling.

- Install tips: 3–5 anchors per 10 m run; tension evenly; use PPE (no kidding—those blades bite).

- Case: a 42-acre logistics park upgraded to Single Loop Spiral Razor Barbed Wire Coil(Coin Type) over chain-link. Theft incidents dropped to zero in 6 months; maintenance logged ≈ 30% lower than the previous concertina setup.

- Feedback: “Clean line, fast to replace damaged sections,” site manager said—short and sweet.

Single Loop Spiral Razor Barbed Wire Coil(Coin Type) is produced in Anping—200 meters North of Huangcheng Village, Hebei, China—arguably the world’s fencing hardware capital. Certificates: ISO, SGS. If your site is coastal or chemically exposed, I’d lean stainless or PVC over standard galvanization.

References

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025