Sep . 12, 2025 07:20 Back to list

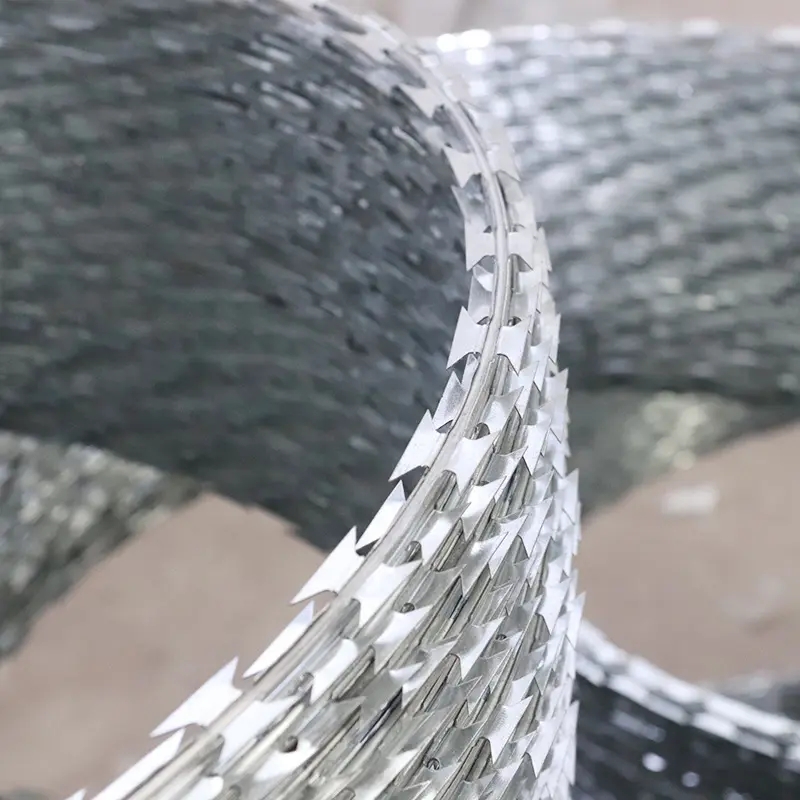

Single Loop Spiral Razor Barbed Wire Coil (Coin Type) - Max Security

Navigating Modern Perimeter Security: Insights into Single Loop Spiral Razor Barbed Wire Coil(Coin Type)

In the evolving landscape of industrial and commercial security, the demand for robust, reliable, and cost-effective perimeter solutions remains paramount. One such critical component is the advanced razor wire system, particularly the Single Loop Spiral Razor Barbed Wire Coil(Coin Type). This specialized barrier, designed for high-deterrence and formidable security, offers a superior alternative to traditional barbed wire in various high-stakes environments.

As security threats become more sophisticated, industries such as petrochemical, energy, defense, critical infrastructure, and data centers are increasingly adopting these advanced physical barriers. The "Coin Type" designation refers to a specific, enhanced barb profile that provides superior cutting and entanglement capabilities, significantly impeding unauthorized access. This article delves into the technical intricacies, application benefits, and strategic considerations for deploying this essential security asset.

Industry Trends and Market Dynamics

The global perimeter security market is experiencing significant growth, driven by increasing geopolitical instability, rising incidents of theft and vandalism, and the imperative to protect critical national infrastructure. Projections indicate the market will exceed USD 25 billion by 2027, with physical barriers like razor wire playing a foundational role. Key trends include the integration of advanced materials for enhanced corrosion resistance and longevity, the development of more aggressive and effective barb designs, and a shift towards solutions that offer ease of deployment without compromising deterrent efficacy.

The demand for Single Loop Spiral Razor Barbed Wire Coil(Coin Type) specifically stems from its balance of high security and relative simplicity in installation compared to complex multi-strand systems. This makes it an ideal choice for rapid deployment in emergent security situations or as an effective upgrade for existing perimeter defenses. Market data from leading security consultancies highlight a consistent year-over-year increase in adoption rates across various industrial sectors seeking robust physical security solutions.

Manufacturing Process Flow: From Raw Material to Advanced Deterrent

The production of Single Loop Spiral Razor Barbed Wire Coil(Coin Type) involves a meticulously controlled process to ensure maximum strength, durability, and deterrent capability. Adherence to international standards like ISO 9001 for quality management is crucial at every stage.

Process Steps:

- 1. Material Selection and Preparation: High-tensile steel strips (typically hot-dip galvanized for corrosion resistance, with zinc coating thickness ranging from 80-275 g/m²) or stainless steel (SS304, SS316 for extreme environments) are selected. Simultaneously, high-carbon steel core wire, also galvanized or stainless, is prepared, known for its high tensile strength (typically 1200-1600 MPa).

- 2. Precision Stamping/Punching: The steel strips are fed into specialized high-speed stamping machines. These machines precisely cut and form the distinctive "Coin Type" razor barbs, characterized by their sharp, aggressive points and reinforcing dimples designed to resist bending.

- 3. Razor Strip Attachment (Crimping): The newly stamped razor strip is mechanically cold-crimped onto the high-tensile core wire. This process ensures a robust, permanent bond, preventing the razor strip from detaching or rotating, which is vital for long-term security performance.

- 4. Single Loop Coiling: The continuous razor barbed wire strand is then fed into a coiling machine that forms it into a single, continuous spiral coil. Unlike concertina wire, these loops are not clipped together, allowing for simpler deployment over existing fences or walls.

- 5. Quality Control and Testing: Each batch undergoes rigorous testing. This includes:

- Tensile Strength Test: To verify core wire and overall strand integrity against ISO 2768 or ASTM A641 standards.

- Zinc Coating Adhesion Test: To ensure galvanization longevity, adhering to ASTM A90/A90M.

- Barb Sharpness and Consistency Check: Visual and tactile inspections to ensure uniform deterrent efficacy.

- Coil Diameter and Loop Spacing: To ensure dimensional consistency for effective deployment.

- 6. Packaging: Finished coils are compressed and securely bound with heavy-duty straps or wrapped in weatherproof material for safe transport and storage.

The typical service life for galvanized steel variants ranges from 7 to 15 years, depending on environmental conditions and zinc coating thickness. Stainless steel options can exceed 25 years. Target industries include petrochemical, oil & gas, metallurgy, mining, power generation, water supply & drainage facilities, military bases, airports, and correctional facilities. In these scenarios, its advantages include superior deterrent effect, excellent corrosion resistance (especially stainless steel variants), and minimal maintenance requirements.

Technical Specifications and Parameters

Understanding the precise technical specifications of Single Loop Spiral Razor Barbed Wire Coil(Coin Type) is crucial for effective security planning and procurement. These parameters dictate its performance, longevity, and suitability for specific applications.

Typical Product Specifications:

| Parameter | Description | Standard Values / Range |

|---|---|---|

| Material | High-tensile steel strip and core wire | Hot-dip Galvanized (HDG) Steel (G90/G210 coating), Stainless Steel (SS304, SS316) |

| Core Wire Diameter | Diameter of the central high-tensile wire | 2.5 mm – 3.0 mm (standard) |

| Razor Blade Thickness | Thickness of the razor barb strip | 0.5 mm – 0.6 mm |

| Barb Length | Length of each individual razor barb | 10 mm – 22 mm (Coin Type profile) |

| Coil Diameter (Installed) | Nominal diameter of the spiral coil when deployed | 450 mm, 500 mm, 600 mm, 750 mm, 900 mm, 1000 mm |

| Number of Loops per Coil | Total number of spiral loops in a standard coil | 30-60 loops (depending on deployed length) |

| Extended Length per Coil | Effective coverage length when fully extended | 7-15 meters (for 450-900mm diameter coils) |

| Tensile Strength (Core Wire) | Strength of the core wire against breaking | Typically 1200-1600 MPa (ISO 2768) |

| Corrosion Resistance | Resistance to rust and environmental degradation | ASTM B117 Salt Spray Test: >500 hours (HDG), >1000 hours (SS) |

These specifications ensure that the razor wire system delivers consistent performance, whether facing harsh weather conditions or determined intrusion attempts. The selection of materials, especially the galvanization levels or stainless steel grade, directly impacts the product's longevity and suitability for coastal, humid, or chemically aggressive environments.

Application Scenarios and Technical Advantages

The strategic deployment of Single Loop Spiral Razor Barbed Wire Coil(Coin Type) provides an unparalleled level of physical deterrence across a broad spectrum of high-security applications. Its robust design is particularly effective where rapid deployment and significant psychological deterrent are required.

Key Application Scenarios:

- Industrial Facilities: Protection of manufacturing plants, warehouses, and storage depots from theft and unauthorized access.

- Critical Infrastructure: Securing power stations, water treatment plants, telecommunication hubs, and data centers, where even minor breaches can have significant consequences.

- Government and Military Installations: Enhancing the perimeter defense of military bases, government buildings, and border control points.

- Petrochemical and Oil & Gas Facilities: Providing layered security for refineries, pipelines, and storage tanks, where security incidents can lead to environmental disasters or economic disruption.

- Correctional Facilities: Adding an essential layer of anti-climb security to prison walls and fences to prevent escapes and unauthorized material entry.

- Airports and Seaports: Reinforcing perimeter security to prevent unauthorized access to sensitive areas and comply with international security regulations.

Technical Advantages:

- High Deterrence Factor: The aggressive Coin Type barbs present a significant psychological and physical barrier, effectively discouraging intrusion attempts.

- Superior Obstruction: Its unique spiral configuration and sharp blades make climbing extremely difficult and hazardous, significantly slowing down or preventing trespassers.

- Material Longevity: Constructed from high-tensile galvanized or stainless steel, offering excellent resistance to corrosion, harsh weather conditions, and UV degradation, leading to extended service life.

- Versatile Deployment: Can be easily installed on top of existing fences, walls, or ground-level as an independent barrier. Its single-loop design simplifies handling compared to complex concertina coils.

- Cost-Effectiveness: Provides a high level of security at a relatively lower material and installation cost compared to electronic surveillance systems or heavy-duty physical walls.

- Low Maintenance: Once installed, it requires minimal ongoing maintenance due to its robust construction and material properties.

Vendor Comparison: Choosing the Right Partner

When procuring perimeter security solutions, selecting a reputable vendor is as critical as the product itself. Factors such as material quality, manufacturing consistency, adherence to international standards, and after-sales support significantly influence the long-term performance and reliability of the Single Loop Spiral Razor Barbed Wire Coil(Coin Type).

Vendor Comparison Matrix:

| Feature/Criterion | Vendor A (Premium) | Vendor B (Standard) | Vendor C (Economy) |

|---|---|---|---|

| Material Grade & Coating | SS304/SS316, HDG (275 g/m²) | HDG (180 g/m²) | HDG (80-120 g/m²) |

| Core Wire Tensile Strength | 1400-1600 MPa (ISO certified) | 1200-1400 MPa (Manufacturer spec) | 1000-1200 MPa |

| Barb Consistency & Sharpness | Excellent, precision-stamped Coin Type | Good, consistent Coin Type | Variable, basic razor profile |

| Certifications | ISO 9001, ASTM, CE | ISO 9001 | Basic Quality Control |

| Corrosion Resistance (Salt Spray Test) | SS: >1500h, HDG: >1000h | HDG: >500h | HDG: >200h |

| Warranty | 10-25 Years | 5-10 Years | 1-3 Years |

A thorough vendor evaluation based on these criteria ensures procurement of a solution that aligns with specific security requirements, budgetary constraints, and expected service life.

Customized Solutions and Application Case Studies

While standard configurations of single loop spiral razor barbed wire coils are highly effective, specific industrial and security environments often necessitate tailored solutions. Customization ensures optimal integration with existing infrastructure and addresses unique threat profiles.

Customization Options:

- Material Variants: Custom orders for specific stainless steel grades (e.g., SS316L for marine environments) or enhanced galvanization levels (e.g., heavily galvanized wire with PVC coating for extreme chemical resistance).

- Coil Diameter and Loop Count: Tailored coil diameters and effective extended lengths to match diverse perimeter heights and spans.

- Barb Profile Adjustments: While "Coin Type" is standard, minor modifications to barb spacing or additional anti-climb features can be explored for ultra-high-security applications.

- Integrated Solutions: Suppliers can offer complete perimeter packages, including razor wire installation accessories (clips, tensioning wire, mounting brackets), fencing systems, and even integration with CCTV or intrusion detection systems.

Application Case Studies:

A critical energy substation in a remote desert region required enhanced perimeter security against potential sabotage and unauthorized entry. Due to extreme temperatures and high sand exposure, durability was key. The solution involved 900mm diameter Single Loop Spiral Razor Barbed Wire Coil(Coin Type), specified with a high-grade HDG (275 g/m²) coating for superior sand abrasion and corrosion resistance. The easy deployment of the single loop system allowed for rapid installation across 2 km of perimeter, significantly bolstering defense against both human and animal intrusion. Customer feedback highlighted the exceptional deterrent value and robust performance under challenging environmental conditions.

To comply with stricter national security directives for critical infrastructure, a municipal water treatment plant needed to upgrade its perimeter. The existing chain-link fence was topped with 600mm stainless steel (SS304) Single Loop Spiral Razor Barbed Wire Coil(Coin Type). The choice of stainless steel was crucial due to the humid, corrosive environment inherent to water treatment facilities. The installation was completed in less than a week, providing a visible and formidable barrier that met stringent security audits. Post-installation reports indicated zero unauthorized breaches and positive feedback from security personnel regarding its ease of integration and long-term viability.

Trustworthiness and Support: FAQ, Lead Time, Warranty

Frequently Asked Questions (FAQ):

A1: Single Loop Spiral Razor Wire consists of individual, unclipped loops, making it easier to deploy over existing structures or in straight lines. Concertina razor wire, conversely, features adjacent loops clipped together at intervals, forming a denser, more formidable barrier but requiring more effort to extend and secure.

A2: Due to the extreme sharpness of the barbs, it is imperative to use heavy-duty gloves (e.g., leather or puncture-resistant), long sleeves, eye protection, and safety boots. Installation should ideally be performed by trained personnel. Specific handling tools are also recommended to avoid direct contact with the blades.

A3: Absolutely. It serves as an excellent first line of physical defense and can be seamlessly integrated with motion sensors, CCTV cameras, and fiber optic intrusion detection systems mounted on fences or walls to create a comprehensive, multi-layered security perimeter.

Lead Time and Fulfillment:

Standard orders for common coil diameters and materials typically have a lead time of 2-4 weeks, depending on order volume and current production schedules. Expedited shipping options are available upon request. For customized solutions or large-scale projects, lead times will be provided with a detailed project proposal, usually ranging from 6-10 weeks to accommodate specific manufacturing requirements and rigorous quality assurance processes. We maintain a robust logistics network to ensure timely delivery globally.

Warranty Commitments:

We stand behind the quality and durability of our Single Loop Spiral Razor Barbed Wire Coil(Coin Type) products. Standard galvanized steel products come with a 5-year warranty against manufacturing defects and premature corrosion under normal operating conditions. Stainless steel variants are covered by an extended 10-year warranty, reflecting their superior material integrity and environmental resistance. Full warranty terms and conditions are available upon request.

Customer Support and After-Sales Service:

Our commitment extends beyond product delivery. We offer comprehensive technical support, including installation guidance, product selection advice, and troubleshooting assistance. Our dedicated customer service team is available via phone and email during business hours to address any inquiries. For complex projects, on-site consultation and supervision services can be arranged to ensure optimal deployment and performance of the razor wire system.

Conclusion: A Reliable Defense for Modern Perimeters

The Single Loop Spiral Razor Barbed Wire Coil(Coin Type) stands as a testament to effective, robust perimeter security. Its precise engineering, high-quality materials, and proven deterrent capabilities make it an indispensable asset for safeguarding critical infrastructure, industrial complexes, and sensitive sites globally. As threats continue to evolve, investing in high-performance physical barriers remains a fundamental strategy for comprehensive security architectures. By understanding its technical specifications, application advantages, and the importance of reputable vendor partnerships, decision-makers can confidently implement this solution to fortify their assets against unauthorized access.

References

- ISO 9001:2015 - Quality Management Systems - Requirements. International Organization for Standardization.

- ASTM A641/A641M - 09 Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire. ASTM International.

- ASTM B117 - 19 Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International.

- "Global Physical Security Market Report." MarketsandMarkets, 2023.

- "The Science of Perimeter Security: Deterrence and Delay." Security Today, 2022.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025