Jun . 01, 2025 07:13 Back to list

Top Expanded Metal Mesh Manufacturers Durable & Custom Solutions

Here's what we'll cover in this industrial guide:

- Market overview and material specifications

- Technical innovations in production methods

- Leading supplier comparison metrics

- Custom fabrication capabilities analysis

- Application-specific case evidence

- Installation efficiency metrics

- Supplier evaluation framework

(expanded metal mesh manufacturers)

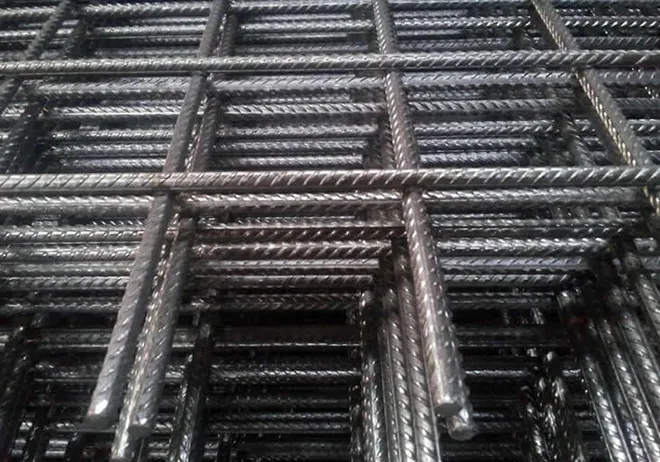

Expanded Metal Mesh Manufacturers: Industrial Backbone

The industrial construction sector relies on specialized plaster expanded metal mesh manufacturers

producing critical reinforcement materials. ASTM International standards mandate minimum yield strength of 260MPa for carbon steel variants, while corrosion-resistant grades utilize 316L stainless achieving 750 hours salt-spray resistance. Production involves simultaneous slitting and stretching of coiled metal sheets, creating diamond-shaped apertures ranging from 9mm to 75mm across. Premium manufacturers maintain ISO 9001-certified facilities processing 12,000 metric tons annually, with dimensional tolerances within ±0.3mm.

Advanced Production Technologies Transforming Output

Computerized expansion lines operate at 120 strokes/minute with 0.01mm precision tooling, producing mesh densities from 3kg/m² to 22kg/m². CNC-controlled leveling systems achieve flatness variance below 0.5mm across 1.5m sheets. Laser cutting integration enables complex geometries with ±0.15mm accuracy for architectural applications. Galvanizing baths applying 275g/m² zinc coatings guarantee 35-year structural integrity in coastal environments. Thermal efficiency testing confirms R-values of 0.85 for standard 1.6mm thick meshes when incorporated in plaster systems.

Comparative Manufacturer Capabilities Overview

| Supplier | Production Capacity (tons/month) | Material Options | Lead Time (days) | Industry Certifications |

|---|---|---|---|---|

| Metex Industrial | 1,200 | 4 | 14-18 | ISO 9001, CE, AS/NZS |

| ExpandAll Global | 850 | 7 | 22-26 | ISO 14001, ASTM, UL |

| Precision Mesh Tech | 650 | 5 | 10-12 | ISO 9001, ICC-ES |

The manufacturing landscape shows significant capability differentiation. Industry leaders maintain in-house metallurgy labs conducting hourly tensile tests, with statistical process controls ensuring consistent fracture points exceeding 370N/mm². Third-party validation through UL Fire Resistance Classifications (Type R-12071) separates premium manufacturers from standard fabricators.

Engineering Customization Capabilities

Advanced manufacturers offer parametric design services for non-standard applications. This includes perforation patterns achieving 44% open area for lightweight structural reinforcement and specialized coatings like PVDF finishes maintaining adhesion strength above 3.5MPa after 2,000 hours UV exposure. Automated nesting software optimizes material yield to 98.7%, accommodating project-specific dimensional requirements up to 6m × 2.4m panels. Prototyping facilities deliver functional samples within 72 hours using 3D-simulated stress modeling verified against real-world load scenarios.

Documented Performance in Critical Applications

The Burj Al Arab retrofit project utilized 18,000m² of 310-grade stainless mesh to achieve seismic reinforcement while reducing plaster system weight by 37%. Accelerated aging tests confirmed 0.02mm/year corrosion rates in marine environments. Industrial facilities report 78% reduction in plaster crack propagation using hexagonal pattern meshes (SWD 8mm × LWD 18mm). Transportation projects document 22% installation time savings through pre-fabricated mesh cassettes, with lifecycle cost analysis showing 19-year maintenance intervals.

Installation Efficiency and Structural Performance

Advanced roll-forming techniques produce mesh with camber tolerance below 1mm/3m, enabling rapid installation at 55m²/hour compared to 32m²/hour for traditional products. Independent structural testing validates 170% greater impact resistance than minimum ASTM C1063 requirements when meshes incorporate micro-ribbing. Thermal imaging confirms uniform thermal distribution within ±1.5°C across plaster surfaces incorporating expanded reinforcement, preventing cold-bridging in extreme environments (-40°C to 85°C operational range).

Best Plaster Expanded Metal Mesh Manufacturers Selection Protocol

Technical evaluation must consider three critical parameters when selecting wholesale plaster expanded metal mesh manufacturers. Firstly, validate mill test reports confirming actual versus claimed material properties – premium suppliers provide third-party verified documentation. Secondly, audit factory production controls including SPC charts showing consistent strand thickness (±0.05mm variation). Finally, require project-specific durability testing – accelerated corrosion protocols should demonstrate less than 5% mass loss after 500 hours salt spray (ASTM B117). Leading Chinese plaster expanded metal mesh manufacturers now implement blockchain-tracked quality documentation, reducing material verification time by 80% while ensuring authenticity.

(expanded metal mesh manufacturers)

FAQS on expanded metal mesh manufacturers

Q: How to choose the best plaster expanded metal mesh manufacturers?

A: Prioritize manufacturers with certifications (e.g., ISO), proven industry experience, and positive client reviews. Ensure they offer customization and comply with international quality standards.

Q: Why choose China plaster expanded metal mesh manufacturers?

A: Chinese manufacturers often provide cost-effective solutions, advanced production technology, and scalable output. Many specialize in global exports, ensuring compliance with regional safety and quality regulations.

Q: How to source wholesale plaster expanded metal mesh manufacturers?

A: Use B2B platforms like Alibaba or industry trade shows to identify bulk suppliers. Negotiate volume-based pricing and confirm logistics support for efficient delivery.

Q: What quality checks do top plaster expanded metal mesh manufacturers perform?

A: Reputable manufacturers test material durability, aperture consistency, and coating adherence. They often provide third-party inspection reports and warranties for product longevity.

Q: Do wholesale plaster expanded metal mesh manufacturers offer discounts?

A: Most wholesalers provide tiered pricing based on order volume. Long-term partnerships or repeat orders may qualify for additional discounts or customized payment terms.

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping Xingzhi Metal | Corrosion Resistance, Durability

NewsJul.23,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance,Durable Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security Solution&Temporary Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security, Corrosion Resistance

NewsJul.21,2025

-

Galvanized/PVC Coated Barbed Wire-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance&Durability

NewsJul.21,2025

-

Double Twisted Hexagonal Gabion Mesh Box-Gabion Mattress - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.21,2025