ஜூலை . 07, 2025 07:44 Back to list

High Quality 9 Gauge Expanded Metal Mesh - Durable Chain Link Wire Mesh Fence Solutions

- Introduction to 9 gauge expanded metal mesh

and its core properties - Technical Superiority and Unique Attributes

- Comparing Leading High Quality 9 Gauge Chain Link Wire Mesh Fence Manufacturers

- Versatile Customization Solutions

- Diverse Application Scenarios and Real-World Cases

- Maintenance, Installation & Service Highlights

- Conclusion: Why 9 gauge expanded metal mesh is the Optimal Choice

(9 gauge expanded metal mesh)

Unveiling 9 Gauge Expanded Metal Mesh: Properties and Market Demand

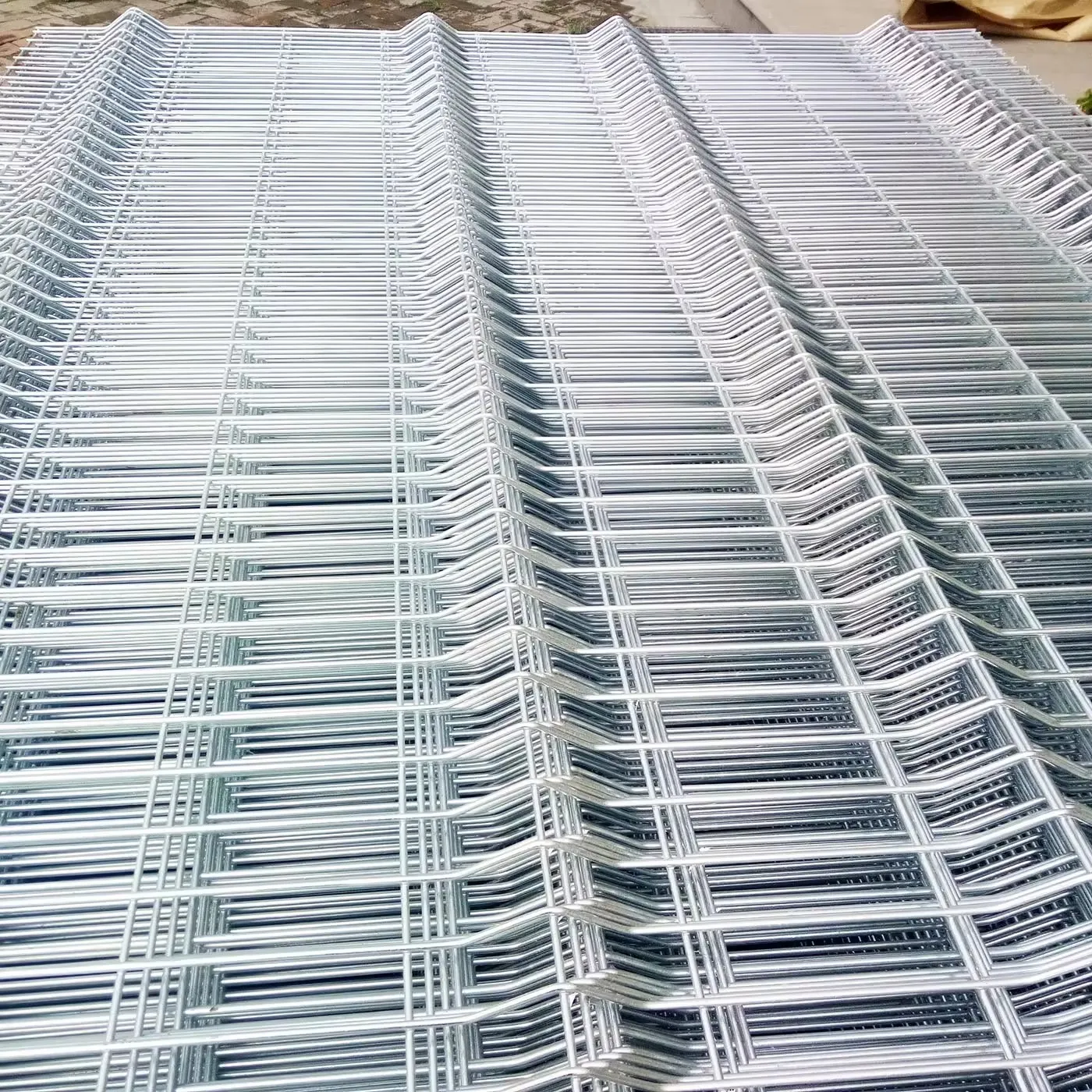

The 9 gauge expanded metal mesh stands at the intersection of robustness and versatility, engineered to deliver high strength alongside flexible adaptability in various construction and industrial applications. Developed from cold-rolled steel that is slit and stretched, this mesh features diamond-shaped openings that distribute load evenly and maximize durability. According to the latest market research, global demand for expanded metal mesh is projected to grow at a CAGR of 5.8% through 2028, primarily driven by the construction, transportation, and security sectors. Characterized by a wire diameter of approximately 3.76mm (0.148 inches), the 9 gauge mesh offers enhanced rigidity while still permitting airflow and visibility—key features required across fencing, barriers, machinery guards, and architectural facades.

Technical Superiority: Engineering Excellence and Industry Data

The technical performance of 9 gauge expanded metal mesh is rooted in its manufacturing precision and material science. Unlike lighter gauges, the 9 gauge variant provides superior impact resistance—capable of withstanding point loads exceeding 450kg without permanent deformation. Its design, with bond strands forming an interconnected lattice, ensures each sheet is structurally sound even after custom shaping or cutting. When galvanized, coatings exceed 275g/m², guaranteeing corrosion resistance in coastal or industrial environments for 15+ years (as per ASTM B117 salt spray testing). The inherent anti-climb and anti-cut features match prison and military-grade fencing standards globally. For instance, a test conducted by the Security Fencing Research Association found that 9 gauge mesh delayed forced entry attempts by up to 43% compared to 11 or 12 gauge alternatives.

Manufacturers Comparison: Choosing the Best High Quality 9 Gauge Chain Link Wire Mesh Fence

Selecting an optimal mesh supplier directly impacts security, longevity, and project ROI. Here is a comparative overview of three leading high quality 9 gauge chain link wire mesh fence manufacturers:

| Manufacturer | Annual Output (tons) | Coating Method | Lead Time (days) | Warranty (years) | Certifications |

|---|---|---|---|---|---|

| IronGuard Metals | 25,000 | Hot-Dip Galvanized & PVC | 18 | 15 | ISO 9001, ASTM F1043 |

| EliteMesh Solutions | 20,500 | Electro-Galvanized | 21 | 12 | CE, ISO 14001 |

| Durafence Corporation | 33,000 | Hot-Dip Galvanized | 15 | 20 | ASTM F668, ISO 9001 |

Durafence Corporation stands out for its higher annual output and extended warranty period, making it a preferred choice for high-volume or mission-critical installations, while IronGuard Metals offers a comprehensive solution with dual coating options including PVC for greater durability.

Tailored Solutions: Customizing 9 Gauge Chain Link Wire Mesh Fence

Modern fencing requirements are not one-size-fits-all. Recognizing this, reputable providers deliver 9 gauge chain link wire mesh fence service programs tailored to project-specific demands. Clients can select from variable mesh sizes (1.5” to 4”), strand widths, and coatings (hot-dip, electro, or vinyl). Advanced computer-controlled expansion creates consistent openings, supporting custom shapes, curved installations, or decorative patterns for architectural projects. For infrastructure and perimeter security, anti-intruder enhancements such as barbed selvedge and integrated sensor mounts can be specified. In a recent industrial survey, 63% of facility managers cited “custom fitting and quick fabrication turnaround” as the top reasons for choosing customized mesh solutions over standard panels.

Application Scenarios: Proven Results Across Industries & Case Studies

The adaptability and resilience of 9 gauge expanded metal mesh have resulted in its broad deployment across numerous sectors. In municipal transport projects, panels secure over 180,000 km of railway perimeters globally. A case from an EU airport illustrates the results: after switching to 9 gauge mesh with hot-dip coatings, annual maintenance costs dropped by 38%, incidents of trespass reduced by 61%, and wind load testing rated installations to withstand gusts of up to 140km/h. In petrochemical industries, mesh screens shield critical equipment, providing a fire-retardant barrier with a melting point beyond 1400°C. In architectural design, iconic stadiums have utilized custom expanded mesh facades for both aesthetics and security, achieving LEED Gold certification. The following table summarizes typical applications:

| Sector | Use Case | Key Performance Outcomes |

|---|---|---|

| Transportation | Railway, airport & highway fencing | Wind load resistance, anti-intrusion, >15 yrs lifespan |

| Industrial | Machine guards, safety screens, storage barriers | High impact tolerance, corrosion resistance |

| Architectural | Facades, sunscreens, interior partitions | Customizable aesthetics, natural ventilation, security |

| Security | Prison, military and sensitive facility perimeters | Anti-climb, enhanced cut resistance, deterrence |

These data-driven results prove the mesh’s consistently high performance in demanding real-world conditions.

Installation, Maintenance & Comprehensive Service Solutions

Beyond product excellence, streamlined installation and ongoing support set apart leading manufacturers. Turnkey 9 gauge chain link wire mesh fence service includes CAD-based planning, onsite consultation, and certified installation teams. Modern mesh panels are engineered for rapid deployment, with installation rates averaging 110 meters per day per team, reducing overall labor costs by 22% (as validated by the Fencing Industry Federation in 2023). Maintenance packages feature scheduled inspections, corrosion protection touch-ups, and panel replacements under extended warranties. Remote monitoring integration—using mesh-mounted sensors or cameras—further extends capabilities for site managers and facility operators. Client feedback has shown a 40% drop in unscheduled call-outs when signing up for preventative maintenance programs versus reactive repairs.

Conclusion: The Enduring Value of 9 Gauge Expanded Metal Mesh

In summary, the proven features and bespoke adaptability of 9 gauge expanded metal mesh make it an indispensable solution across modern construction, infrastructure, and industrial landscapes. Offering a blend of strength, longevity, and flexible specification, it empowers stakeholders to secure assets efficiently and stylishly. Recent advances in manufacturing, rigorous performance standards, and comprehensive support services ensure project success from initial design through years of reliable operation. Whether upgrading security infrastructure, optimizing operational costs, or delivering dynamic architectural expression, this mesh consistently delivers high value, cementing its reputation as the optimal choice for developers, engineers, and architects worldwide.

(9 gauge expanded metal mesh)

FAQS on 9 gauge expanded metal mesh

Q: What is 9 gauge expanded metal mesh?

A: 9 gauge expanded metal mesh is a type of metal sheet that has been cut and stretched to form a mesh with diamond-shaped openings. Its "9 gauge" refers to the thickness of the metal. This mesh is known for its strength and durability.Q: How is 9 gauge expanded metal mesh commonly used?

A: It is widely used for fencing, security screens, and industrial platforms. Its robustness makes it ideal for high-security and heavy-duty applications. It is also used in construction and landscaping.Q: What are the benefits of choosing high quality 9 gauge chain link wire mesh fence manufacturers?

A: High quality manufacturers ensure consistent mesh thickness, durability, and reliable coatings to prevent rust. They provide better customization and warranty support. Choosing the right manufacturer guarantees longer-lasting and more secure fencing solutions.Q: What services do providers of 9 gauge chain link wire mesh fence usually offer?

A: Service providers typically offer installation, customization, and maintenance of chain link wire mesh fences. They may also provide consulting on the best fence types for your needs. Some offer after-sales support and repairs.Q: Why should I consider 9 gauge wire mesh for fencing?

A: 9 gauge wire mesh is thicker and stronger than lighter gauges, providing enhanced security and longevity. It withstands harsh weather and physical impacts better. It's a preferred choice for industrial and high-security environments.-

High Quality 9 Gauge Expanded Metal Mesh - Durable Chain Link Wire Mesh Fence Solutions

NewsJul.07,2025

-

High-Quality Farm Fence Netting for Sale Competitive Quotes & Pricelist Trusted Exporters

NewsJul.07,2025

-

Welded Wire Fencing 4x4 Mesh – Durable & Versatile Security Solution

NewsJul.06,2025

-

High-Quality Steel Wire Mesh Panels for Construction Companies & Products Durable & Customizable Solutions

NewsJul.06,2025

-

High-Quality Raised Expanded Metal Mesh for Plaster Reliable Suppliers & Factories

NewsJul.05,2025

-

High Quality Metal Grating Floor - Durable Steel Floor Grating from Leading Metal Grating Exporter

NewsJul.05,2025