- ஆப்பிரிக்க

- அல்பேனியன்

- அம்ஹாரிக்

- அரபு

- ஆர்மேனியன்

- அஜர்பைஜானி

- பாஸ்க்

- பெலாரசியன்

- பெங்காலி

- போஸ்னியன்

- பல்கேரியன்

- கற்றலான்

- செபுவானோ

- சீனா

- சீனா (தைவான்)

- கோர்சிகன்

- குரோஷியன்

- செக்

- டேனிஷ்

- டச்சு

- ஆங்கிலம்

- எஸ்பெராண்டோ

- எஸ்டோனியன்

- ஃபின்னிஷ்

- பிரெஞ்சு

- ஃப்ரிஷியன்

- காலிசியன்

- ஜார்ஜியன்

- ஜெர்மன்

- கிரேக்கம்

- குஜராத்தி

- ஹைட்டியன் கிரியோல்

- ஹவுசா

- ஹவாய்

- ஹீப்ரு

- இல்லை

- மியாவ்

- ஹங்கேரிய

- ஐஸ்லாந்து

- இக்போ

- இந்தோனேஷியன்

- ஐரிஷ்

- இத்தாலிய

- ஜப்பானியர்

- ஜாவானியர்கள்

- கன்னடம்

- கசாக்

- கெமர்

- ருவாண்டன்

- கொரியன்

- குர்திஷ்

- கிர்கிஸ்

- தொழிலாளர்

- லத்தீன்

- லாட்வியன்

- லிதுவேனியன்

- லக்சம்பர்கிஷ்

- மாசிடோனியன்

- மல்காஷி

- மலாய்

- மலையாளம்

- மால்டிஸ்

- மௌரி

- மராத்தி

- மங்கோலியன்

- மியான்மர்

- நேபாளி

- நார்வேஜியன்

- நார்வேஜியன்

- ஆக்ஸிடன்

- பாஷ்டோ

- பாரசீக

- போலிஷ்

- போர்த்துகீசியம்

- பஞ்சாபி

- ரோமானியன்

- ரஷ்யன்

- சமோவான்

- ஸ்காட்டிஷ் கேலிக்

- செர்பியன்

- ஆங்கிலம்

- ஷோனா

- சிந்தி

- சிங்களம்

- ஸ்லோவாக்

- ஸ்லோவேனியன்

- சோமாலி

- ஸ்பானிஷ்

- சுண்டனீஸ்

- சுவாஹிலி

- ஸ்வீடிஷ்

- தகலாக்

- தாஜிக்

- தமிழ்

- டாடர்

- தெலுங்கு

- தாய்

- துருக்கிய

- துர்க்மென்

- உக்ரைனியன்

- உருது

- உய்குர்

- உஸ்பெக்

- வியட்நாமியர்

- வெல்ஷ்

- உதவி

- இத்திஷ்

- யாருப்பா

- ஜூலு

செப் . 08, 2025 14:27 மீண்டும் பட்டியலில்

Welded Razor Wire Mesh: Galvanized/PVC Coated Security Fencing

Strategic Perimeter Security: The Role of Advanced Welded Razor Wire Mesh

In the evolving landscape of industrial and critical infrastructure security, the demand for robust, reliable, and durable perimeter solutions has never been more pronounced. Facilities ranging from petrochemical plants and military installations to data centers and correctional institutions require security measures that act as formidable deterrents while offering long-term protection. This necessitates advanced material science and engineering in security fencing.

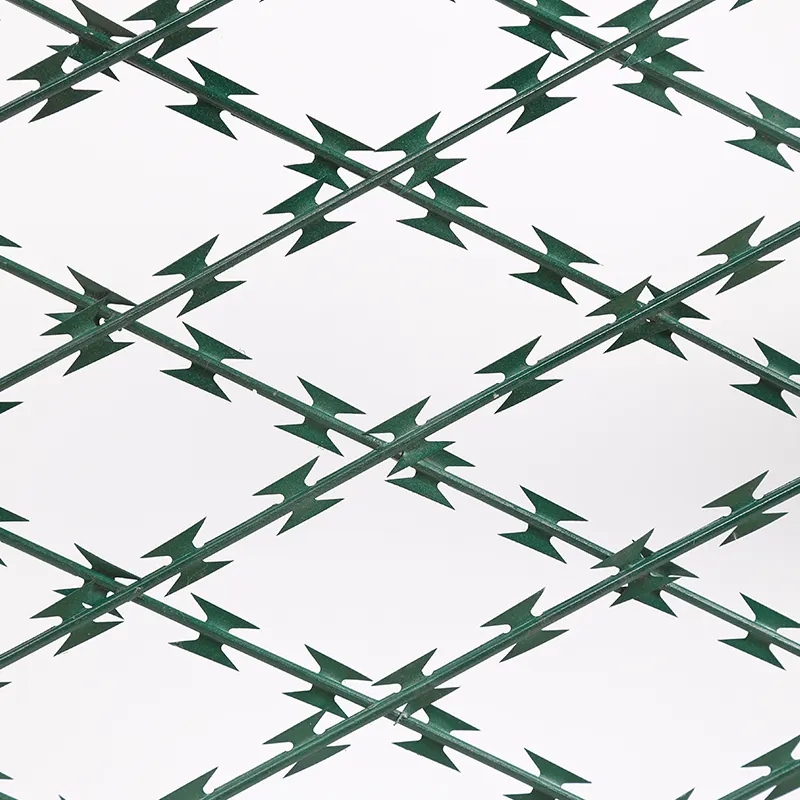

Among the most effective solutions available today is the வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ். This specialized fencing material combines the inherent strength of welded wire mesh with the severe deterrent capabilities of razor wire, further enhanced by protective coatings to ensure maximum longevity and performance in diverse environmental conditions. Its design integrates multiple layers of security, offering both a physical barrier and a psychological deterrent to unauthorized access, making it a cornerstone for comprehensive security strategies.

Industry Trends and Market Outlook for High-Security Fencing

The global security fencing market is experiencing significant growth, driven by escalating security threats, increased investments in infrastructure development, and stringent regulatory requirements across various sectors. According to recent industry analyses, the market is projected to reach over $5 billion by 2028, with a compound annual growth rate (CAGR) exceeding 6%. Key drivers include the expansion of industrial facilities, the need for enhanced border security, and the protection of critical national infrastructure such as energy grids, water treatment plants, and telecommunications hubs.

Emerging trends indicate a shift towards integrated security solutions, where physical barriers like high-security fences are combined with surveillance systems, access control, and intelligent monitoring. There's also a rising preference for materials offering superior durability and corrosion resistance, reducing the total cost of ownership over the fence's lifecycle. Products like வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ், with their advanced protective coatings and robust construction, are at the forefront of this trend, meeting the demand for low-maintenance, high-performance security perimeters in challenging environments.

Furthermore, environmental considerations are influencing material choices, with a growing emphasis on coatings that are environmentally compliant and manufacturing processes that adhere to sustainable practices. The convergence of these factors underscores the critical importance of selecting advanced fencing solutions that are not only effective but also economically and environmentally responsible.

Understanding the Product: Technical Specifications and Material Excellence

The efficacy of வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் stems from its carefully engineered composition and superior material properties. This product is typically manufactured from high-tensile steel wire, ensuring exceptional resistance to cutting and deformation. The core wire, often high-carbon steel, is chosen for its strength and resilience, critical for a formidable security barrier.

Key Technical Parameters:

- Wire Gauge: Ranging from 12 to 16 gauge (2.0mm to 2.7mm), determining the mesh's robustness. Lower gauge numbers (thicker wire) are preferred for security applications.

- Mesh Opening: Common sizes include 50x50mm, 75x75mm, 100x100mm, designed to prevent easy climbing or cutting. Smaller openings enhance security.

- Razor Type: Various blade profiles are utilized, such as BTO-22 (Blade Type Obstacle 22), CBT-60 (Concertina Blade Type 60), offering different levels of deterrence and injury potential. The blades are pressed onto the wire, creating sharp barbs.

- Galvanization: Primarily hot-dip galvanization (HDG) per ASTM A123 or ISO 1461 standards, applying a zinc coating typically 40-300 g/m². This provides cathodic protection against rust and corrosion. Electro-galvanization is also used for lighter protection.

- PVC Coating: An additional layer of polyvinyl chloride (PVC) is applied over the galvanized wire. This coating, usually 0.5mm to 1.0mm thick, provides enhanced UV resistance, further corrosion protection, and aesthetic benefits, allowing for integration into various environments.

- Tensile Strength: The wire typically exhibits a tensile strength of 300-500 MPa, ensuring it can withstand significant force without breaking.

- Adhesion: Both the zinc and PVC coatings are rigorously tested for adhesion to ensure they do not delaminate, even under stress or impact, prolonging the effective service life.

Product Specification Table: Welded Razor Wire Mesh

| Parameter | Typical Specification Range | Unit/Standard |

|---|---|---|

| Wire Material | High-Carbon Steel (Q195, Q235) | SAE 1006-1008 |

| Core Wire Diameter | 2.0 - 2.7 mm | Gauge 12-16 |

| கண்ணி திறப்பு | 50x50 mm, 75x75 mm, 100x100 mm | மிமீ |

| Razor Blade Type | BTO-22, BTO-30, CBT-60, CBT-65 | N/A |

| Zinc Coating Weight (Hot-dip) | 40 - 300 g/m² | ASTM A123 / ISO 1461 |

| PVC Coating Thickness | 0.5 - 1.0 mm | மிமீ |

| இழுவிசை வலிமை | 300 - 500 MPa | N/mm² |

| பேனல் உயரம் | 1.2 m, 1.5 m, 1.8 m, 2.0 m, 2.4 m | m |

| Panel Length | 2.0 m, 2.5 m, 3.0 m | m |

These parameters can be customized to meet specific security requirements and environmental challenges, ensuring optimal performance and longevity for the intended application.

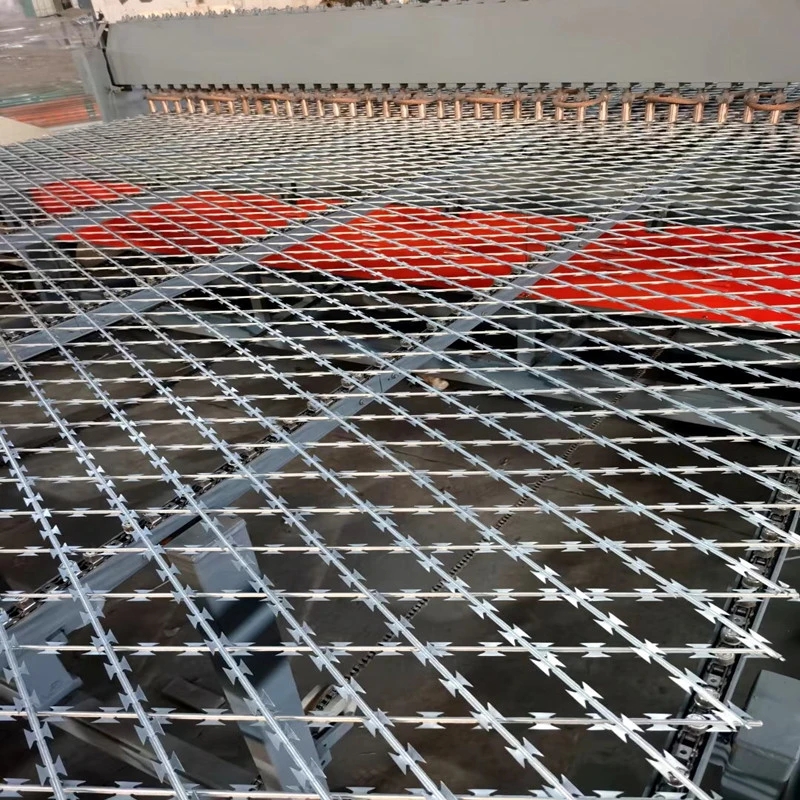

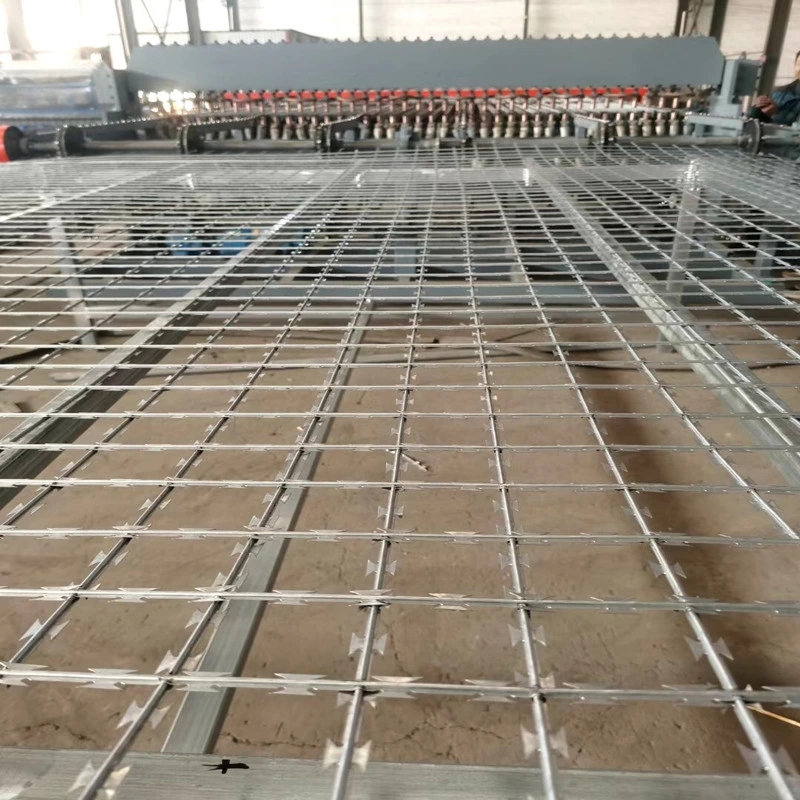

The Manufacturing Process: Precision Engineering for Superior Protection

The production of வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் is a multi-stage process that emphasizes precision, material integrity, and advanced coating technologies. This stringent process ensures the final product meets the highest standards for security, durability, and corrosion resistance.

Process Flow Overview:

- Raw Material Selection & Preparation: High-quality, high-carbon steel wire rods (e.g., SAE 1006-1008) are selected for their tensile strength and ductility. These rods undergo cold drawing to achieve the desired wire gauge, ensuring uniform diameter and enhanced strength.

- Razor Blade Fabrication: Steel sheets (often galvanized) are precisely punched and stamped to form the distinct razor blade profiles (e.g., BTO-22, CBT-60). These blades are then cold-pressed onto a core wire, forming the razor wire coils.

- Welding of Mesh Panels: The straightened core wires are fed into automated welding machines. Resistance welding is employed to fuse horizontal and vertical wires at their intersections, creating a strong, rigid mesh panel. This process ensures consistent mesh opening and exceptional structural integrity, preventing individual wires from being easily separated.

- Pre-treatment (Cleaning & Degreasing): Post-welding, the mesh panels undergo a thorough cleaning process. This involves alkaline degreasing and acid pickling to remove oils, rust, scales, and other impurities from the steel surface. This step is crucial for optimal adhesion of subsequent coatings.

- Hot-Dip Galvanization: The cleaned mesh panels are immersed in a bath of molten zinc at approximately 450°C (840°F). During this hot-dip galvanization process, a metallurgical bond forms between the steel and zinc, creating a durable, sacrificial coating that provides superior corrosion resistance. The zinc layer typically adheres to ISO 1461 or ASTM A123 standards for coating thickness and uniformity.

- PVC Coating Application: After galvanization and cooling, the panels are pre-heated to a specific temperature. They are then moved to a fluidized bed where finely powdered PVC plastic is applied. The heated metal causes the PVC powder to melt and fuse onto the surface, forming a continuous, uniform, and highly adherent polymer layer. Alternatively, extrusion coating may be used for some profiles. The panels are then cured to ensure proper cross-linking of the PVC.

- Quality Control and Testing: Throughout the entire process, rigorous quality control checks are performed. This includes testing wire tensile strength, mesh weld integrity, zinc coating weight and adhesion (e.g., Preece test, bend test), PVC coating thickness and adhesion, UV resistance, and salt spray resistance (ASTM B117) to ensure compliance with international standards and product specifications.

- Finishing and Packaging: Finally, the finished வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் panels are inspected, trimmed, and securely packaged for transportation, often stacked on pallets with protective wrapping.

Target Industries:

- Petrochemical Facilities: For securing highly volatile and sensitive areas.

- Metallurgy & Mining: Protecting valuable assets and dangerous zones.

- Water Supply & Drainage Infrastructure: Safeguarding critical utility sites.

- Power Generation & Substations: Preventing unauthorized access to high-voltage equipment.

- Correctional Institutions & Military Bases: Maximizing security and deterrence.

Key Advantages in Typical Application Scenarios:

- Corrosion Resistance: The dual-layer protection (galvanization + PVC) offers unparalleled resistance to harsh weather, chemical exposure, and saline environments, significantly extending service life.

- Enhanced Security: The combination of robust welded mesh and razor sharp blades creates a formidable barrier, deterring intrusion and making unauthorized climbing extremely difficult.

- Energy Saving: By extending the fence's lifespan and reducing maintenance requirements, facilities save on labor, material, and operational costs associated with frequent repairs or replacements. This contributes to a lower total cost of ownership over decades.

Application Scenarios: Securing Critical Assets Across Industries

The versatility and high-security attributes of வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் make it an ideal choice for a multitude of demanding environments. Its ability to withstand extreme conditions and provide a significant deterrent level is unmatched.

Key Application Areas:

- Correctional Facilities and Prisons: Essential for maintaining high-security perimeters, preventing escapes, and controlling inmate movements. The razor wire component provides an immediate and severe deterrent.

- Military Bases and National Borders: Used extensively to define and protect sensitive military zones and critical border crossings, effectively deterring illegal entry.

- Industrial Complexes and Factories: Securing valuable inventory, machinery, and sensitive production areas from theft and vandalism.

- Power Plants and Utility Substations: Protecting vital energy infrastructure from sabotage, terrorism, and unauthorized access, ensuring continuous operation.

- Airports and Seaports: Reinforcing perimeter security to comply with international aviation and maritime security regulations, preventing breaches in highly controlled environments.

- Data Centers and Telecommunication Hubs: Safeguarding critical data infrastructure, where any physical breach could lead to significant financial and operational losses.

- Chemical and Petrochemical Facilities: Providing secure perimeters for hazardous material storage and processing units, mitigating risks of industrial espionage or sabotage.

In these scenarios, the mesh's robust construction and deterrent capabilities minimize the need for constant human surveillance in certain areas, thereby optimizing security resource allocation and enhancing overall operational efficiency.

Technical Advantages and Performance Metrics

The distinct technical advantages of வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் position it as a premium choice for high-security applications. These advantages are a direct result of its carefully engineered design and manufacturing processes.

Foremost Advantages Include:

- Superior Corrosion Resistance: The dual protection of hot-dip galvanization and PVC coating provides an exceptional barrier against rust, oxidation, and chemical degradation. Zinc offers cathodic protection, corroding preferentially to steel, while the PVC layer acts as a physical shield, impervious to many environmental aggressors. This significantly extends the fence's operational life, even in highly corrosive marine or industrial atmospheres, minimizing the need for frequent replacement or extensive maintenance.

- Enhanced Security and Deterrence: The welded mesh construction ensures robust structural integrity, making it difficult to cut or climb. Coupled with the razor sharp blades, it presents an extreme physical barrier and a formidable psychological deterrent. This multi-layered defense makes unauthorized penetration highly improbable without specialized tools and significant time, alerting security personnel effectively.

- Exceptional Longevity and Low Maintenance: Due to its superior protective coatings and high-tensile wire, this fencing solution offers an extended service life, often exceeding 20-30 years. This longevity translates into reduced lifecycle costs, as the expenses associated with regular painting, rust treatment, or premature replacement are virtually eliminated. Its resilience against environmental factors ensures consistent performance with minimal upkeep.

- High Impact Resistance: The rigid, welded grid structure, combined with high-strength steel, allows the fence to absorb and distribute impact forces effectively, resisting attempts at forced entry or vehicle ramming.

- Aesthetic Versatility: While primarily functional, the PVC coating offers a range of color options (e.g., green, black, grey), allowing the fence to blend more harmoniously with the surrounding environment or to match corporate branding, without compromising security.

- Ease of Installation: Despite its robust nature, the mesh panels are designed for relatively straightforward installation using appropriate posts and fastening systems, allowing for efficient deployment across large perimeters.

Vendor Comparison and Selection Criteria

Choosing the right supplier for வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் is paramount to ensuring the long-term effectiveness and value of your security investment. While many manufacturers offer similar products, key differentiators exist in material quality, manufacturing precision, and commitment to international standards.

Critical Factors for Vendor Evaluation:

- Material Quality and Sourcing: Verify that the vendor uses high-grade steel wire (e.g., specified carbon content) and authentic zinc for galvanization. Inferior materials compromise strength and corrosion resistance.

- Coating Standards and Adherence: Ensure the manufacturer rigorously adheres to established galvanization standards (e.g., ASTM A123, ISO 1461) and PVC coating thickness/adhesion specifications. Request test reports or certifications.

- Manufacturing Precision and Technology: Assess the manufacturer's welding technology, automation levels, and quality control processes to ensure consistent mesh integrity and razor blade attachment.

- Customization Capabilities: A reputable vendor should offer flexible customization options for mesh size, wire gauge, razor type, panel dimensions, and PVC color to match specific project requirements.

- Lead Time and Logistics: Evaluate their capacity to meet project deadlines and their logistical capabilities for international shipping and delivery.

- Certifications and Compliance: Prioritize suppliers holding ISO 9001 quality management certifications and those whose products comply with relevant international security and environmental standards.

- After-Sales Support and Warranty: A comprehensive warranty and responsive after-sales service are indicators of a manufacturer's confidence in their product and commitment to customer satisfaction.

Product Comparison: XZ Metal vs. Generic Supplier

| அம்சம் | XZ Metal Standard | Generic Supplier (Typical) |

|---|---|---|

| Core Wire Material | High-Carbon Steel (SAE 1006-1008) | Low-Carbon Steel (Variable Quality) |

| Galvanization Standard | ASTM A123 / ISO 1461 (Min. 275 g/m²) | Electro-galvanized or lower HDG (Max. 60 g/m²) |

| PVC Coating Thickness | Uniform 0.8 - 1.0 mm (UV Stabilized) | Variable 0.3 - 0.5 mm (Often without UV stabilizer) |

| Weld Integrity | Automated Resistance Welding, 99% Fusion Rate | Manual or semi-automated, inconsistent welds |

| Corrosion Resistance | Excellent (20+ years service life) | Moderate (5-10 years service life) |

| Certifications | ISO 9001:2015, ASTM, CE | Limited or N/A |

This comparison highlights the importance of scrutinizing technical specifications and certifications. Investing in a higher-quality product from a reputable vendor like XZ Metal typically results in significantly greater long-term value, superior security, and reduced operational costs.

Customized Solutions: Tailoring Security for Unique Needs

Recognizing that no two security challenges are identical, leading manufacturers of வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் offer extensive customization options. This flexibility ensures that security perimeters are not merely off-the-shelf solutions but are precisely engineered to meet the unique topographical, environmental, and threat-level demands of each project.

Customization Parameters Include:

- Mesh Dimensions: Panels can be produced in specific heights and lengths to perfectly integrate with existing infrastructure or to achieve desired coverage without unnecessary cutting and waste.

- Wire Gauge and Aperture Size: Custom wire diameters and mesh openings can be specified to adjust the rigidity and penetration resistance, from standard security to ultra-high-security applications.

- Razor Blade Configuration: Different razor blade types (e.g., BTO-22, CBT-60, flat wrap coils) can be integrated, or specific spacing between razor elements can be adjusted to optimize deterrence based on risk assessment.

- Coating Specifications: While standard galvanization and PVC thicknesses are common, bespoke zinc coating weights or PVC formulations (e.g., enhanced fire retardancy, anti-graffiti properties) can be developed for specialized environmental challenges.

- Color Matching: PVC coating colors can be custom-matched to blend seamlessly with natural surroundings (e.g., forest green) or to align with specific architectural or corporate branding requirements (e.g., dark grey, black).

- Integrated Solutions: Manufacturers can provide complementary components such as specialized fence posts, gates, access control points, and mounting hardware, all designed to integrate perfectly with the razor wire mesh panels.

This ability to tailor every aspect of the fence system ensures not only superior security performance but also optimal cost-effectiveness by avoiding over- or under-engineered solutions. Expert consultation during the planning phase is crucial to define these customized requirements accurately.

Real-World Application Case Studies

Case Study 1: High-Security Perimeter for a National Power Grid Substation

Client: National Energy Infrastructure Provider

Location: Remote, high-exposure mountainous region

Challenge: The substation required an impenetrable perimeter to protect against vandalism, theft of copper, and potential sabotage. The remote location meant minimal surveillance and extreme weather conditions, demanding a long-lasting, maintenance-free solution.

Solution: XZ Metal supplied a custom-height வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் system. The mesh utilized 2.5mm high-tensile wire with 75x75mm openings, hot-dip galvanized to ASTM A123 standards (275 g/m² zinc), and subsequently coated with a 1.0mm dark green UV-stabilized PVC layer. BTO-22 razor coils were integrated into the top section. The specialized coating ensured superior corrosion resistance against snow, ice, and heavy rainfall, extending the fence's projected service life to over 25 years with minimal intervention. The razor wire acted as a primary deterrent, significantly reducing the attractiveness of the site for illicit activities, and freeing up security personnel for monitoring other critical areas.

Outcome: The installation resulted in a robust, visually imposing barrier that drastically reduced incidents of trespassing and attempted theft. The low maintenance requirements have significantly lowered operational costs over time, proving the long-term value of the investment.

Case Study 2: Border Security Reinforcement for a High-Risk Region

Client: Government Border Protection Agency

Location: Arid, dusty border stretch

Challenge: The agency required a highly effective physical barrier along a critical border segment prone to illegal crossings. The environment was characterized by intense UV radiation, extreme temperature fluctuations, and abrasive wind-blown sand, demanding a fence material with exceptional durability and resilience.

Solution: A specialized deployment of XZ Metal's வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் was implemented. The solution featured extra-thick (3.0mm) galvanized wire to increase physical resilience against cutting tools, combined with a bespoke beige-colored PVC coating formulated for enhanced UV stability and abrasion resistance. CBT-65 razor wire was densely integrated along the entire fence line, providing maximum deterrence. The panels were designed for rapid deployment and interlocking, allowing for efficient coverage of extensive border sections.

Outcome: The reinforced border fence significantly reduced unauthorized cross-border movements, acting as a crucial first line of defense. The advanced PVC coating withstood the harsh desert conditions without degradation, ensuring consistent security performance and extended service life, which was critical for remote and difficult-to-access border areas. This project demonstrated the product's adaptability and robustness in the most challenging environments.

Ensuring Trust: Certifications, Warranty, and Support

Trust is paramount in B2B relationships, especially when it concerns critical infrastructure security. Reputable manufacturers demonstrate their commitment to quality, reliability, and customer satisfaction through verifiable certifications, clear warranty policies, and robust support systems.

Authoritativeness through Certifications:

XZ Metal adheres to stringent international quality management and product standards. Our manufacturing processes for வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் are certified under:

- ISO 9001:2015: This certification confirms our adherence to a robust quality management system, ensuring consistent product quality from raw material sourcing to final delivery.

- ASTM A123 / A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products, guaranteeing the quality and thickness of our galvanization.

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods, another critical standard for coating quality.

- CE Marking: Compliance with European Union safety, health, and environmental protection directives, for products exported to the EU.

These certifications are not merely badges; they represent an ongoing commitment to excellence and a promise of product performance, verified by independent third-party auditors. We regularly provide detailed test reports (e.g., salt spray tests, adhesion tests, tensile strength reports) to clients for complete transparency.

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of Galvanized/PVC Coated Welded Razor Wire Mesh for Fence?

A1: With proper installation and maintenance, our வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் is designed for a service life exceeding 20-30 years in most environments. The dual-layer protection significantly enhances longevity compared to single-coated alternatives.

Q2: Can the mesh be customized for specific project dimensions or color requirements?

A2: Absolutely. We offer extensive customization options for panel height, length, wire gauge, mesh aperture, razor blade type, and PVC color. Our technical team works closely with clients to design solutions that perfectly match project specifications.

Q3: What kind of maintenance is required for this fencing?

A3: Due to its galvanized and PVC-coated finish, the fence requires minimal maintenance. Routine inspections for physical damage or debris are recommended, but repainting or rust treatment is generally not necessary for decades.

Q4: Is installation complex? Do you offer guidance?

A4: While robust, installation is straightforward for experienced contractors. We provide detailed installation manuals and technical support to ensure correct and safe deployment. For large or complex projects, we can offer on-site consultation or recommend certified installation partners.

Q5: How do the razor blades affect safety for authorized personnel?

A5: The razor blades are designed as a severe deterrent to intruders. For authorized personnel, safety protocols including appropriate personal protective equipment (PPE) and adherence to safe operating procedures are essential during installation and maintenance. The fence design inherently prevents casual contact for personnel operating within the secured perimeter.

Logistics, Warranty, and After-Sales Support

Lead Time & Fulfillment:

At XZ Metal, we understand the critical nature of project timelines. Standard orders for வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் typically have a lead time of 2-4 weeks, depending on order volume and customization requirements. Expedited manufacturing and shipping options are available for urgent projects. Our logistics team manages global shipping, ensuring timely and secure delivery to your project site, adhering to international shipping regulations and documentation standards.

Warranty Commitments:

We stand behind the quality and durability of our products. XZ Metal offers a comprehensive 10-year warranty against manufacturing defects and significant corrosion that impairs the structural integrity of the வேலிக்கான கால்வனேற்றப்பட்ட/பிவிசி பூசப்பட்ட வெல்டட் ரேஸர் வயர் மெஷ் under normal environmental conditions. This warranty reflects our confidence in our materials and processes, providing clients with peace of mind regarding their long-term security investment. Specific warranty terms and conditions are provided with each quotation.

Customer Support & After-Sales Service:

Our commitment to our clients extends far beyond product delivery. XZ Metal provides dedicated technical support throughout the project lifecycle, from initial consultation and design to installation and post-commissioning. Our expert team is available to answer technical queries, provide troubleshooting assistance, and offer guidance on maintenance best practices. For any concerns or inquiries, our customer service department is accessible via phone, email, and our online portal, ensuring prompt and effective resolution.

References

- ASTM International. "A123/A123M-17, Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products." ASTM.org.

- International Organization for Standardization. "ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods." ISO.org.

- Grand View Research. "Security Fencing Market Size, Share & Trends Analysis Report." GrandViewResearch.com.

- NACE International (now AMPP). "Corrosion Protection of Materials." AMPP.org.

- European Committee for Standardization. "EN 10244-2: Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings." CEN.eu.

-

Durable River Bank Gabion Mesh Solutions for Protection

செய்திNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

செய்திNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

செய்திNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

செய்திNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

செய்திNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

செய்திNov.17,2025