- Afrikalı

- Arnavut

- Amharca

- Arapça

- Ermeni

- Azerice

- Bask

- Belarusça

- Bengalce

- Boşnakça

- Bulgarca

- Katalanca

- Cebuano

- Çin

- Çin (Tayvan)

- Korsikalı

- Hırvat

- Çek

- Danimarkalı

- Flemenkçe

- İngilizce

- Esperanto

- Estonyalı

- Fince

- Fransızca

- Frizce

- Galiçyaca

- Gürcü

- Almanca

- Yunan

- Gujarati

- Haiti Kreyolu

- ev

- hawaii

- İbranice

- Hayır

- miao

- Macarca

- İzlandaca

- ibo

- Endonezya dili

- İrlandalı

- İtalyan

- Japonca

- Cava

- Kannada

- Kazak

- Khmer

- Ruandalı

- Koreli

- Kürt

- Kırgız

- İş gücü

- Latince

- Letonca

- Litvanyalı

- Lüksemburgca

- makedonca

- malgaşi

- Malayca

- Malayalam

- Malta

- Maori

- Marathi

- Moğolca

- Myanmar

- Nepalce

- Norveççe

- Norveççe

- Oksitanca

- Peştuca

- Farsça

- Lehçe

- Portekizce

- Pencapça

- Romence

- Rusça

- Samoalı

- İskoç Galcesi

- Sırpça

- İngilizce

- Shona

- Sintçe

- Sinhala

- Slovak

- Slovence

- Somalili

- İspanyol

- Sundan dili

- Svahili

- İsveççe

- Tagalogca

- Tacikçe

- Tamilce

- Tatar

- Telugu

- Tayland

- Türkçe

- Türkmen

- Ukrayna

- Urduca

- Uygur

- Özbekçe

- Vietnam

- Galce

- Yardım

- Yidiş

- Yoruba

- Zulu

Haz . 04, 2025 13:55 Listeye geri dön

Choosing the Right Wire Mesh Products

In modern construction, manufacturing, and even agriculture, wire mesh products have become essential due to their versatility, strength, and adaptability. Whether you're designing a security barrier, filtering industrial materials, or creating custom architectural features, choosing the right mesh can drastically influence the outcome. The range of wire mesh products on the market today allows buyers to find solutions tailored to strength, opening size, corrosion resistance, and overall design. These products are often the invisible backbone of many systems, supporting structures, sorting materials, or serving as safety barriers. With their wide range of applications, the growing demand has also encouraged innovation among global suppliers and manufacturers.

Understanding the Variety: Exploring Wire Mesh Types for Different Needs

When selecting mesh for a specific project, knowing the available wire mesh types is essential. Welded wire mesh is widely used for its rigidity and strength—it’s a top choice for fencing, cages, and concrete reinforcement. Woven wire mesh, created by interlacing wires, is flexible and more suited for filtration or screen applications in industries like mining or food processing. Expanded metal mesh is made by slitting and stretching metal sheets, forming diamond-shaped openings ideal for walkways and protective guards. Crimped wire mesh, with its corrugated wires, provides added grip and dimensional stability for heavy-duty uses. Each of these wire mesh types can be selected in various weaves and gauges, offering flexibility in airflow, visibility, strength, and material flow. Whether it's for sieving, shielding, fencing, or architectural detailing, understanding mesh configurations ensures you match the form to the function.

Choosing the Best Wire Mesh Material for Durability and Performance

The base wire mesh material plays a crucial role in how well the mesh performs over time, especially under environmental stress. Stainless steel is a premium option, known for its corrosion resistance and long service life—it’s preferred in food processing, chemical, and marine applications. Galvanized steel, coated in zinc, offers decent rust resistance at a lower cost, making it suitable for agricultural fencing and construction supports. For indoor or dry-area use, low-carbon steel offers affordability and adequate strength. Copper and brass meshes provide excellent electrical conductivity and are often used in EMI shielding and decorative applications. For high-temperature or corrosive environments, specialty alloys like Monel or Inconel are selected. Plastic-coated or PVC-dipped meshes offer weather resistance and aesthetic appeal, especially in residential fencing. Matching the wire mesh material to your specific environment—whether it's exposure to moisture, chemicals, or physical wear—is key to maximizing value and performance.

Partnering with the Right Wire Mesh Company for Custom and Bulk Orders

Choosing a reputable wire mesh company ensures you get consistent quality, technical support, and supply chain reliability. Leading manufacturers typically offer extensive catalogs with customizable options in weave pattern, wire diameter, panel size, and coatings. A strong wire mesh company will provide samples, material test certifications, and compliance with international standards such as ASTM or ISO. They’ll also support large-volume orders with logistical capabilities like timely delivery, proper packaging, and on-site stock. Whether you’re sourcing mesh for an industrial project, infrastructure development, or a creative installation, a trusted supplier helps avoid costly delays and material incompatibility. Consider companies that offer value-added services such as laser cutting, custom framing, or powder coating. With rising global demand, sourcing from a wire mesh company with robust production and quality control processes offers peace of mind, especially for high-spec projects.

Wire Mesh Applications: From Industry to Innovation

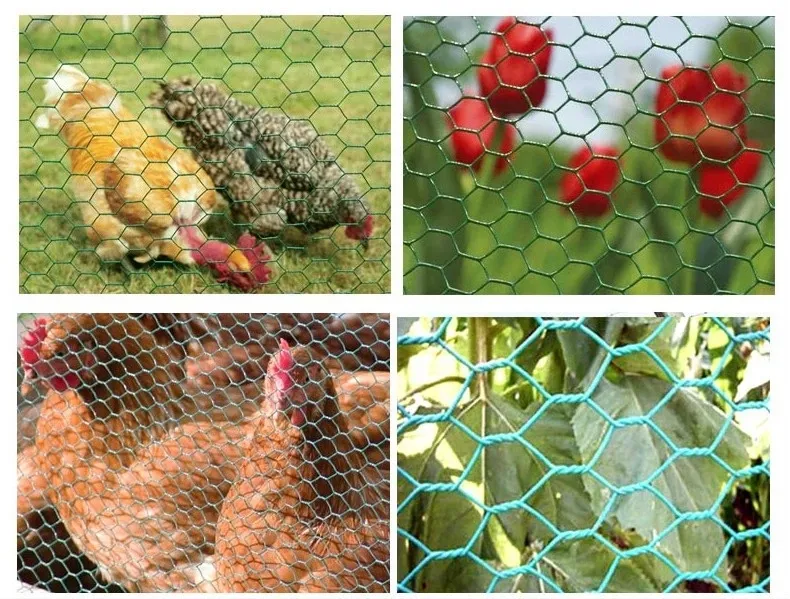

The adaptability of wire mesh products makes them invaluable across sectors. In construction, mesh reinforces concrete slabs and secures perimeters with heavy-duty fencing. In agriculture, wire mesh supports trellises, protects crops, and forms livestock enclosures. In industrial filtration, different wire mesh types are used to separate particles, strain liquids, or even shield sensitive components from electromagnetic interference. Architects and designers also embrace mesh for ceilings, facades, sunshades, and stair balustrades—balancing utility and modern aesthetics. Mesh panels are even seen in furniture and lighting fixtures. The choice of wire mesh material, whether it’s corrosion-resistant stainless steel or visually appealing brass, impacts both function and form. The rise of green building solutions has also encouraged the use of recyclable wire mesh in eco-friendly construction. As manufacturing processes evolve, laser-cut and precision-woven mesh continues to open new possibilities across industries, from security to art.

wire mesh FAQs

What are the most common wire mesh types used in construction?

Welded wire mesh and crimped wire mesh are widely used in construction. Welded mesh provides strength for concrete reinforcement and fencing, while crimped mesh is valued for its grip and structural stability.

How do I select the right wire mesh material for outdoor use?

Stainless steel and galvanized steel are both great for outdoor applications. Stainless steel offers the best corrosion resistance, while galvanized mesh is more economical for temporary or moderate exposure environments.

Can wire mesh products be customized?

Yes, most wire mesh companies offer customization in mesh size, wire thickness, panel dimensions, and coatings. This ensures the mesh fits perfectly with your technical and aesthetic requirements.

What industries rely heavily on wire mesh products?

Construction, agriculture, mining, automotive, aerospace, and architectural design all rely on wire mesh for strength, filtration, shielding, safety, and visual effects.

How do I find a reliable wire mesh company for bulk supply?

Look for a company with a broad product catalog, quality certifications, and the ability to deliver at scale. Good suppliers also offer technical consultation, samples, and after-sales support to ensure your needs are fully met.

-

Durable River Bank Gabion Mesh Solutions for Protection

HaberlerNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

HaberlerNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

HaberlerNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

HaberlerNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

HaberlerNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

HaberlerNov.17,2025