Sep . 29, 2025 22:15 Back to list

Galvanized Iron Wire Anti Insect & Mosquito Window Screen?

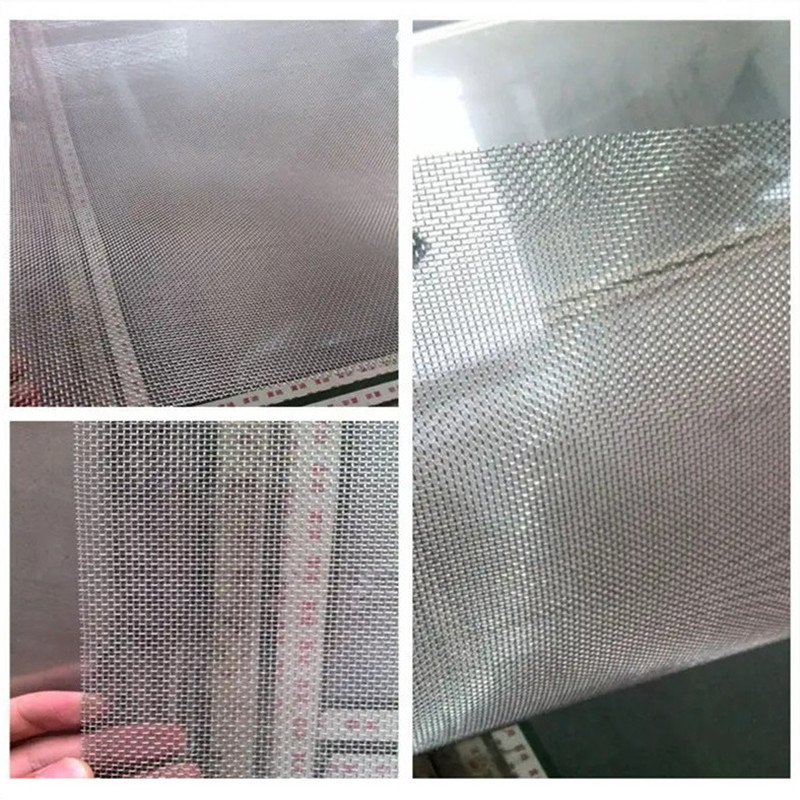

Galvanized Iron Wire Anti Insect & Mosquito Mesh Window Screen Net

Demand for durable, low-maintenance insect protection is climbing, especially with urban densification and health departments pushing vector-control. It seems that contractors are moving away from short-lived fiberglass toward stronger, recyclable metals. Our Galvanized Iron Wire Anti Insect & Mosquito Mesh Window Screen Net hits that sweet spot of strength, airflow, and cost control—many customers say it “just lasts longer,” which, to be honest, is what counts on site.

Technical Specifications (core models)

| Material | Low-carbon steel iron wire (pre-galvanized or hot-dip), also available in stainless or aluminum on request |

| Mesh count | 14×14, 16×14, 18×16, 20×20 (others by request) |

| Wire diameter | ≈0.18–0.28 mm (real-world use may vary) |

| Zinc coating (typ.) | ≈30–80 g/m² per ASTM A641 / EN 10244-2 classes |

| Tensile strength | ≈350–550 MPa |

| Roll size | 0.8–1.5 m width × 25–30 m length (custom sizes available) |

| Surface/Finish | Electro-galvanized or hot-dip galvanized; passivated |

| Certifications | ISO, SGS; compliance with ASTM E2016/ISO 9044 where applicable |

Process Flow, Testing, and Service Life

- Materials: low-carbon steel drawn to fine diameters; zinc-coated per ASTM A641 or EN 10244-2.

- Methods: precision weaving (plain weave), edge trimming, straightening, tension leveling.

- Optional: post-weave passivation for added corrosion resistance.

- Testing: mesh count and aperture (ASTM E2016/ISO 9044), zinc thickness (magnetic gauge), adhesion, NSS salt spray ≈120–240 h per ISO 9227/ASTM B117.

- Service life: ≈5–10 years outdoors (rural/suburban); shorter in coastal/industrial unless upgraded coating.

Origin: 200meters North Of Huangcheng Village, Anping, Hebei, China.

Applications and Advantages

Used for residential windows and doors, hospitality retrofits, poultry houses, food plants (non-contact areas), and municipal facilities. Actually, airflow is noticeably better than many coated fabrics at similar insect exclusion levels.

- High strength vs fiberglass; resists pet scratches.

- Corrosion-resistant zinc layer; good UV stability.

- Clean look, easy to wash; recyclable metal.

- Cost-efficient compared to stainless, with solid longevity.

Customization

Mesh count, aperture, roll width/length, wire gauge, and finish (electro vs hot-dip; even black/grey coatings on request). Frames and spline kits available around project specs.

Field Data and Mini Case Studies

- Salt spray test (NSS): 168 h, red rust ≤5% edges only (sample lot; lab data; around typical performance).

- Airflow: ≈65–75% open area for 18×16 mesh; pressure drop modest at residential wind speeds.

Hotel retrofit, coastal city: 18×16 hot-dip mesh cut maintenance visits by ≈30% over 12 months; guests reported fewer insects without “stuffy rooms.”

Poultry farm, humid zone: Upgraded from fiberglass to galvanized; screen damage rate fell from 9% to ≈2% per season. Payback in under one year, surprisingly fast.

Vendor Comparison (indicative)

| Criteria | XZ Metal (Factory) | Vendor A (Trading) | Vendor B (OEM) |

|---|---|---|---|

| Lead time | 7–15 days | 15–25 days | 10–20 days |

| Certificates | ISO, SGS | SGS (partial) | ISO |

| Customization | Mesh/width/coating tailored | Limited | Moderate |

| QC & testing | In-house + third-party on request | Third-party only | In-house |

Logistics: FOB Tianjin/Qingdao; MOQ around 50–100 rolls depending on spec. Packaging: moisture barrier + edge protectors.

If you need reliable insect exclusion without the usual sagging or early corrosion, this Galvanized Iron Wire Anti Insect & Mosquito Mesh Window Screen Net is a practical, proven choice.

Authoritative citations

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire.

- EN 10244-2 – Steel wire and wire products. Non-ferrous metallic coatings on steel wire.

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth.

- ISO 9044 – Industrial woven wire cloth – Technical requirements and tests.

- ISO 9227 / ASTM B117 – Corrosion tests in artificial atmospheres (salt spray).

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025