- Африка

- Албан

- Амхар

- Гарәп

- Әрмән

- Азәрбайҗан

- Баск

- Беларусия

- Бенгал

- Босния

- Болгар

- Каталан

- Себуано

- Китай

- Китай (Тайвань)

- Корсика

- Хорватия

- Чехия

- Дания

- Голландия

- Инглиз

- Эсперанто

- Эстония

- Фин

- Француз

- Фриз

- Галисия

- Грузин

- Немец

- Грек

- Гуджарати

- Гаити креолы

- hausa

- hawaiian

- Иврит

- .К

- Миао

- Венгр

- Исландия

- игбо

- Индонезия

- ириш

- Италия

- Япон

- Ява

- Каннада

- казах

- Кхмер

- Руанда

- Корея

- Көрд

- Кыргызстан

- Хезмәт

- Латин

- Латвия

- Литва

- Люксембург

- Македония

- Малгаши

- Малайча

- Малаялам

- Мальта

- Маори

- Марат

- Монгол

- Мьянма

- Непал

- Норвегия

- Норвегия

- Окитан

- Пушту

- Фарсы

- Поляк

- Португал

- Пәнҗаби

- Румыния

- Рус

- Самоа

- Шотландия Гэль

- Серб

- Инглиз

- Шона

- Синдхи

- Синхала

- Словакия

- Словения

- Сомали

- Испан

- Сундан

- Суахили

- Швед

- Тагалог

- Таҗик

- Тамил

- Татар

- Телугу

- Тай

- Төрек

- Төрекмәнстан

- Украин

- Урду

- Уйгур

- Uzbekзбәк

- Вьетнам

- Уэльс

- Ярдәм итегез

- Идиш

- Йоруба

- Зулу

Окт . 27, 2025 10:13 Исемлеккә кире кайту

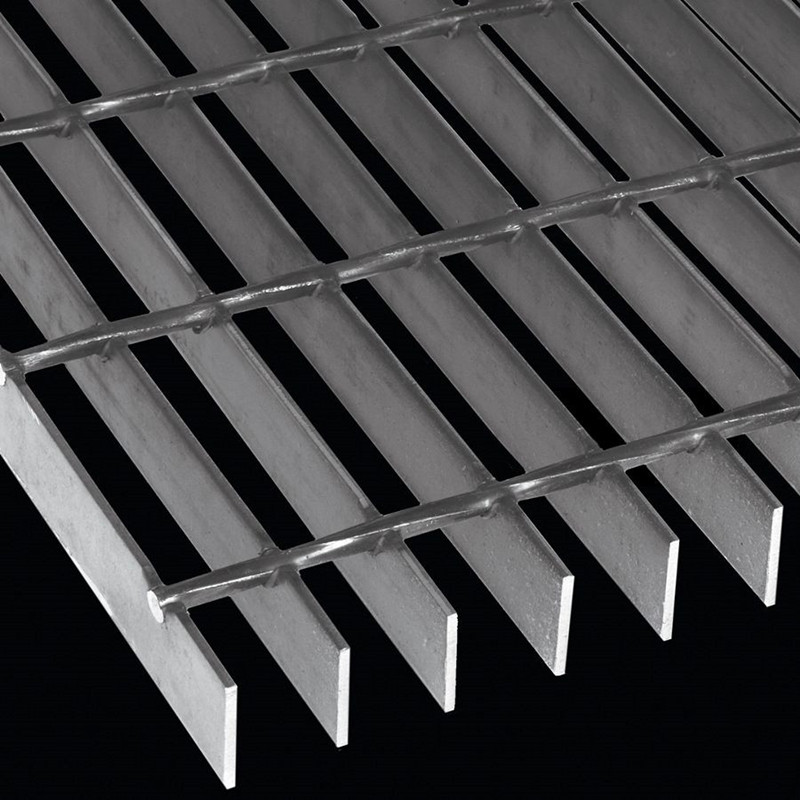

Hot Dipped Galvanized Steel Grating/Bar Grating - Anti-Slip

Гальванизацияләнгән корыч торлау / бар торлау is a key solution in the manufacturing industry, specifically within Fabricated metal products and Metal structure manufacturing. This article explores how Anping County Xingzhi Metal Wiremesh Products Co.,Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Hot Dipped Galvanized Steel Grating/Bar Grating Overview

- Benefits & Use Cases of Hot Dipped Galvanized Steel Grating/Bar Grating in Metal structure manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Hot Dipped Galvanized Steel Grating/Bar Grating from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

Hot Dipped Galvanized Steel Grating/Bar Grating Overview

Hot dipped galvanized steel grating, also known as bar grating, is a load-bearing flooring and decking solution composed of parallel bearing bars connected by cross bars, then protected by a zinc coating through hot dip galvanizing. In Fabricated metal products and Metal structure manufacturing, it is the go-to choice for platforms, mezzanines, trench covers, catwalks, and stair treads where strength, drainage, ventilation, and slip resistance are essential. Galvanizing after fabrication forms a metallurgical bond between zinc and steel, creating long-term corrosion resistance—critical for chemical plants, energy facilities, and outdoor infrastructure.

Common configurations include welded or press-locked grating, plain or serrated bearing bars, and banded panels for added rigidity. Typical bearing bar thicknesses and spacings can be tailored to meet project load and deflection requirements, with serrated tops improving slip resistance in oily or wet environments. Zinc coating thickness is commonly specified to recognized industry standards (e.g., EN ISO 1461 or ASTM A123 equivalents) to help ensure predictable service life. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd manufactures custom sizes, cut-outs, and accessories (toe plates, nosings, and fixing clips) to fit seamlessly into OEM equipment, structural frames, and modular platforms.

Benefits & Use Cases of Гальванизацияләнгән корыч торлау / бар торлау in Metal structure manufacturing

In metal structure manufacturing, hot dipped galvanized steel grating/bar grating excels in high-traffic platforms, access walkways around process equipment, pipe racks, drainage trenches, and safety stairs. Its open grid design enhances airflow and light penetration, reduces dust buildup, and allows liquids to pass through—ideal for fabrication shops, foundries, mining operations, power plants, and food processing areas. For outdoor use, the galvanized coating protects against moisture, de-icing salts, and industrial atmospheres, supporting longer maintenance intervals and reliable uptime.

- Safety and compliance: serrated surfaces improve traction; optional toe plates and nosings support safer edges on platforms and stairs.

- Strength-to-weight efficiency: high load capacity with minimal dead load simplifies steel frame design and installation logistics.

- Customization: precise cut-outs for columns, handrail posts, and equipment nozzles; panel banding for edge stiffness; rapid clip fastening.

Anping County Xingzhi Metal Wiremesh Products Co.,Ltd leverages disciplined fabrication and quality control to deliver consistent panel flatness, accurate bar spacing, and clean galvanizing finishes. The team supports engineering take-offs, drawing reviews, and delivery planning—helping B2B decision makers compress timelines from RFQ to commissioning while maintaining predictable quality on repetitive or multi-site orders.

Cost, Maintenance & User Experience

Total cost of ownership for hot dipped galvanized steel grating/bar grating is driven by long service life, minimal maintenance, and straightforward installation. The zinc coating provides sacrificial protection, delaying corrosion and reducing repainting or replacement cycles. Compared with painted carbon steel plates or checker plate, galvanized bar grating typically requires only periodic inspection and cleaning—no annual coating touch-ups. For many industrial atmospheres, the expected service life of a properly galvanized system can span multiple decades, improving lifecycle ROI and reducing shutdown events.

Fabricated metal product manufacturers and EPC teams often cite faster field fit-up due to lighter panels and standardized clips, resulting in shorter crane time and less labor. End users appreciate the slip resistance of serrated bearing bars and the drainage that keeps surfaces drier and cleaner. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd supports unit-cost efficiency through batch fabrication, nesting optimization, and careful packaging to minimize transport damage. The outcome is a durable, low-maintenance flooring system that helps plants maintain safety and reliability while controlling operating costs.

Sustainability & Market Trends in manufacturing

Sustainability priorities are reshaping procurement across manufacturing. Steel is one of the most recycled materials globally, and galvanized steel grating is fully recyclable at end-of-life. Long-lived assets reduce replacement frequency, lowering embodied carbon over the lifecycle. Specifying hot dipped galvanized steel grating/bar grating can support programs aiming to align with modern durability standards and circularity goals while maintaining worker safety and operational resilience. Additionally, open-grid designs reduce the need for frequent cleaning chemicals versus solid plate flooring, indirectly supporting lower environmental impact in some applications.

Market demand is trending toward modular platforms, expedited installs, and standardized components that simplify global rollouts. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd positions itself as a forward-thinking partner by offering custom panelization, consistent quality, and consultative support for specification alignment. The company can produce to recognized galvanizing and fabrication standards upon request and works closely with buyers to optimize packaging, logistics, and documentation—important in international supply chains striving to reduce waste and emissions.

Conclusion on Hot Dipped Galvanized Steel Grating/Bar Grating from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

Hot dipped galvanized steel grating/bar grating delivers the strength, safety, and longevity required in manufacturing, Fabricated metal products, and Metal structure manufacturing. With robust corrosion protection, excellent slip resistance, and flexible customization, it supports safer platforms, efficient installs, and a lower total cost of ownership. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd is a dependable manufacturer focused on precision fabrication, quality finishes, and responsive service—making them a smart choice for B2B decision makers seeking reliable, scalable supply.

- Contact us: email: sales2@xzmetal.com

- Visit our website: https://www.xzmetal.com

-

Durable River Bank Gabion Mesh Solutions for Protection

ЯңалыкларNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

ЯңалыкларNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

ЯңалыкларNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

ЯңалыкларNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

ЯңалыкларNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

ЯңалыкларNov.17,2025