Oct . 16, 2025 14:21 Back to list

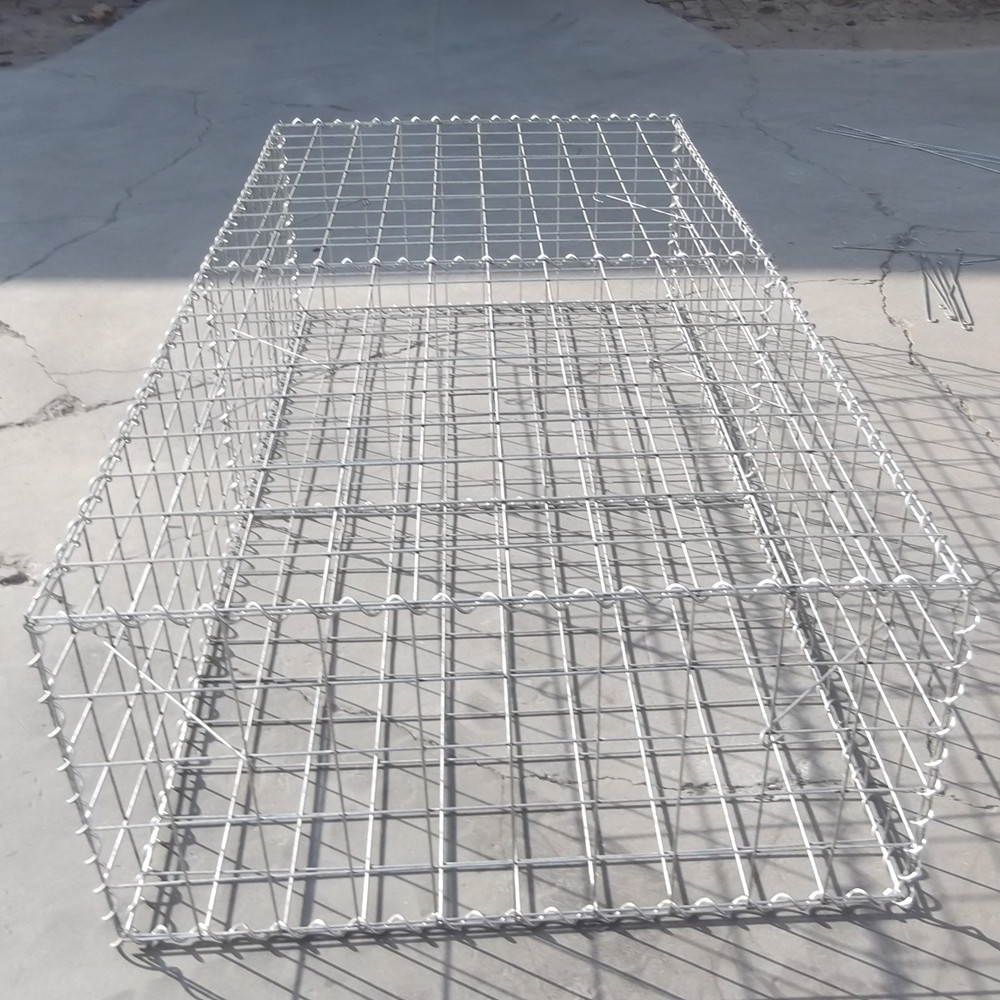

Galvanized Welded Wire Mesh Gabion Box/Basket – Long-Lasting

Galvanized Welded Wire Mesh Gabion Box/Basket: field notes from a changing jobsite

I’ve been walking riverbanks and highway cuts long enough to notice a shift: engineers are moving from loose rock plus guesswork to predictable, testable systems. Welded gabions are part of that shift. Made in Anping, Hebei—200 meters north of Huangcheng Village, if you know the road—these cages tame slopes, eat up energy from water, and frankly, make site managers sleep better. Many customers say installation is faster than they expected, which tracks with what I’ve seen on crews.

What’s inside the box (and why it matters)

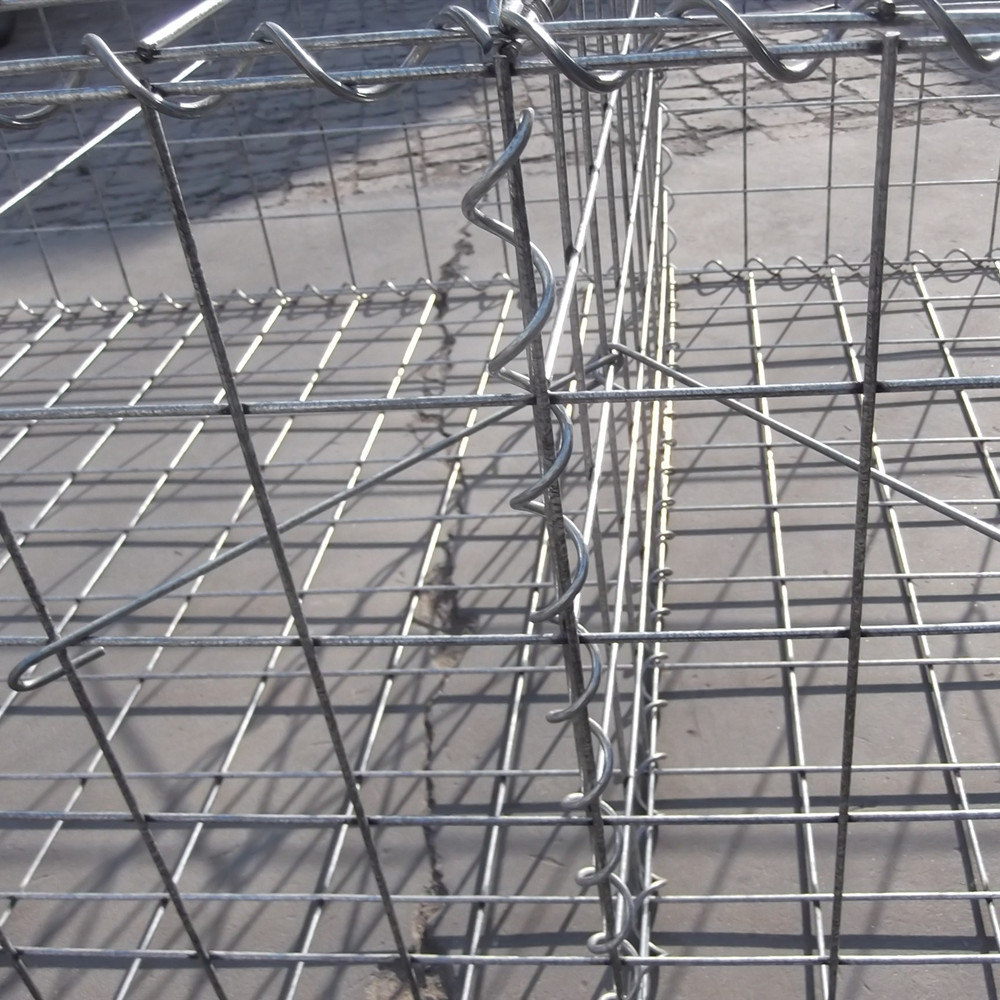

Core materials are Q195 or Q235 low-carbon steel wire, welded, then protected by heavy galvanizing or Galfan (Zn-5%Al-MM). That’s the short version. The longer version involves choosing wire diameter, mesh aperture, coating mass, and how often to insert diaphragms to control rock movement. In fact, the right diaphragm spacing is what keeps walls looking sharp five winters later.

| Parameter | Typical Range (≈, real-world use may vary) |

|---|---|

| Wire Material | Q195 / Q235 |

| Wire Diameter | 3.0–5.0 mm (core); 2.2–3.0 mm lacing |

| Mesh Aperture | 50×50, 75×75, 100×100 mm |

| Standard Box Sizes | 1×1×2 m; 0.5×1×2 m; custom on request |

| Coating Options | Zinc Z200–Z350; Galfan 5%Al 200–300 g/m² |

| Tensile Strength | ≈ 380–550 MPa (wire) |

| Weld Shear | ≥ 75% of wire strength (per EN guidance) |

| Certificates | ISO; SGS test reports available |

Process flow, testing, and service life

Materials are drawn, straightened, and welded on automated lines; panels are then cut, edge-wired, and assembled with diaphragms. Coatings follow ISO 1461 (hot-dip) or EN 10244-2 (zinc) practices. Typical lab checks include weld shear, coating mass, aperture tolerance, and salt spray (ASTM B117/ISO 9227). With Galfan, I’ve seen 1,000–2,000 h salt spray hold-up; hot-dip zinc does fine inland but, honestly, go Galfan near brackish water. Service life? Around 25–50 years coastal, 50+ inland—site chemistry is the decider.

Where they’re used (and what crews say)

- Riverbank armor, headwalls, and apron mats

- Highway cut stabilization and noise berms

- Mine haul-road shoulders; drainage swales

- Landscaping terraces that don’t look “engineered”

Feedback tends to repeat: “fewer field adjustments,” “clean alignment,” and “nice finish even after backfill.” The rigidity of Galvanized Welded Wire Mesh Gabion Box/Basket panels speeds up level courses. However, plan rock size correctly—oversized angular rock locks best.

Vendor snapshot: what to look for

| Criteria | XZ Metal (Anping) | Importer A | Local Fabricator B |

|---|---|---|---|

| Wire grade | Q195/Q235 traceable | Varies by lot | Usually Q235 |

| Coating options | Zinc or Galfan | Mostly zinc | Zinc; Galfan on request |

| Weld shear QA | Routine EN-based tests | Batch certificates | Shop tests |

| Lead time | Fast for standard sizes | Import-dependent | Quick for small runs |

| Customization | Full: mesh, size, diaphragms | Limited | Flexible locally |

| Price level | Competitive FOB | Mid—logistics add-on | Higher/unit |

Customization tips

Specify aperture to suit rock size; add diaphragms every 1 m; choose Galfan near salt or de-icing. Spiral binders speed assembly; lacing wire is classic and strong. If aesthetics matter, ask for uniform panel squareness. And yes, Galvanized Welded Wire Mesh Gabion Box/Basket can be powder over zinc for architectural work—just be realistic about chips during filling.

Mini case files

Sichuan river training: 1×1×2 m boxes, 4.0 mm wire, Galfan coat. Salt-spray tested to 1,200 h. Crew reported 20% faster install vs hex-mesh due to panel stiffness.

Foothill terrace, California: 0.5 m steps, 75×75 mm mesh for a cleaner face. Owner said the look “beats railroad ties” and the wall rode out a wet winter without settlement.

Final thought: specs win bids, but execution wins seasons. If you need drawings, test sheets, or custom pallets, ask early. The good vendors will say yes before you finish the sentence.

Authoritative citations

- EN 10223-8: Steel wire and wire products — Part 8: Welded mesh gabions.

- ASTM A1064/A1064M: Standard Specification for Steel Wire and Welded Wire Reinforcement.

- ASTM A641/A641M: Zinc-Coated (Galvanized) Carbon Steel Wire.

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- ISO 9227 / ASTM B117: Corrosion tests in artificial atmospheres—salt spray.

- CIRIA C683: The Rock Manual—coastal and river engineering guidance (gabions included).

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025