Sep . 29, 2025 22:15 Back to list

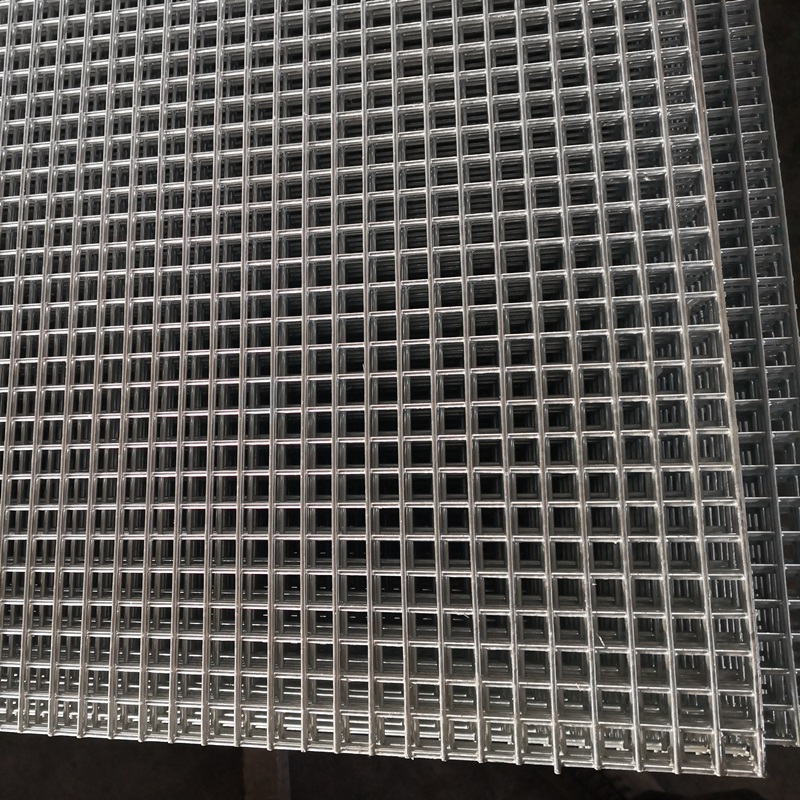

Welded wire mesh panels and rolls – Galvanized, SS, Custom

Welded wire mesh panels and rolls: 2025 Buyer’s Guide

From construction rebar alternatives to smart perimeter fencing, demand is shifting toward higher-zinc, longer-life meshes and quicker on-site installation. Many customers say they want fewer surprises—consistent welds, flatness that behaves, and coatings that don’t chalk after one season. Origin: 200 meters North Of Huangcheng Village, Anping, Hebei, China.

Industry trends (short version)

- Hot-dip galvanizing and PVC-over-galv are winning due to lifecycle cost. - Tighter tolerances for robotics and prefab. - Sustainability reports request material traceability and ISO certificates. To be honest, documentation matters almost as much as the steel.

Process flow and QA

Materials: Low-carbon Q195 or Q235 wire rod → drawn to diameter. Methods: resistance spot welding on CNC lines; coatings: electro-galvanized, hot-dip galvanized, PVC coated, or industrial painting. Testing: weld shear tests, aperture tolerance, zinc thickness checks per ISO 1461/EN 10244-2, salt-spray benchmarking per ASTM B117. Service life: ≈ 5–25 years depending on coating and environment (real-world use may vary). Industries: construction, fence, agriculture, animal cages, gabion, mining screens, HVAC guards.

Specification snapshot

| Parameter | Typical range (≈) | Notes |

|---|---|---|

| Wire diameter | 1.0–6.0 mm | Q195/Q235, UTS around 350–550 MPa |

| Aperture (mesh) | 12.7×12.7 to 200×200 mm | Tighter mesh available |

| Panel size | 1×2 m to 2.4×6 m | Flatness control ±2 mm/m |

| Roll size | 0.9–2.0 m width, 15–30 m length | For fencing, cages |

| Coating | EG, HDG, PVC, paint | Zinc ≈ 40–275 g/m²; PVC 0.4–1.0 mm |

Applications: concrete reinforcement, perimeter fence, animal cages, partition walls, gabion box infill, machine guards. In fact, Welded wire mesh panels and rolls are a bit of a universal toolkit for site managers.

Advantages and customization

- Consistent apertures and load paths vs. woven mesh. - Faster installs; fewer ties. - Custom wire gauges, mesh openings, panel/roll sizes, colors (PVC), and packaging. Actually, many buyers ask for private-label tags and QR-coded bundles—easy enough.

Case notes (real-world)

- Logistics park (EU): HDG 4.0 mm, 50×200 mm panels reduced fence maintenance by ≈ 35% in 24 months. - Poultry farm (SEA): PVC-coated 2.5 mm rolls improved corrosion resistance near coastal air; customer feedback: “no red rust after monsoon season,” which is encouraging, however we still suggest annual washdowns.

Vendor comparison (indicative)

| Vendor | Coating options | Lead time (≈) | Docs |

|---|---|---|---|

| XZ Metal (ISO9001) | EG / HDG / PVC / Paint | 10–25 days | Mill certs, CoC, test reports |

| Vendor B | EG / HDG | 15–35 days | Basic CoC |

| Vendor C | PVC only | 20–40 days | On request |

Standards, certification, and sample test data

Certifications: ISO9001 quality system. Conformance: ASTM A1064 for welded wire reinforcement, ISO 1461/EN 10244-2 for zinc, and optional salt spray benchmarking per ASTM B117. Internal lab snapshots: HDG panels achieved 240 h salt-spray with no red rust; weld shear ≥ 75% of wire UTS (around values; field exposure can differ). It seems that Welded wire mesh panels and rolls with PVC-over-galv perform best in coastal sites.

References:

- ASTM A1064/A1064M—Standard Specification for Steel Wire and Welded Wire Reinforcement.

- ISO 1461—Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM B117—Standard Practice for Operating Salt Spray (Fog) Apparatus.

- EN 10244-2—Steel wire and wire products—Non-ferrous metallic coatings on steel wire—Part 2: Zinc or zinc alloy coatings.

- ISO 9001:2015—Quality management systems—Requirements.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025