Welcome to our websites!

Th1 . 24, 2025 04:11 Back to list

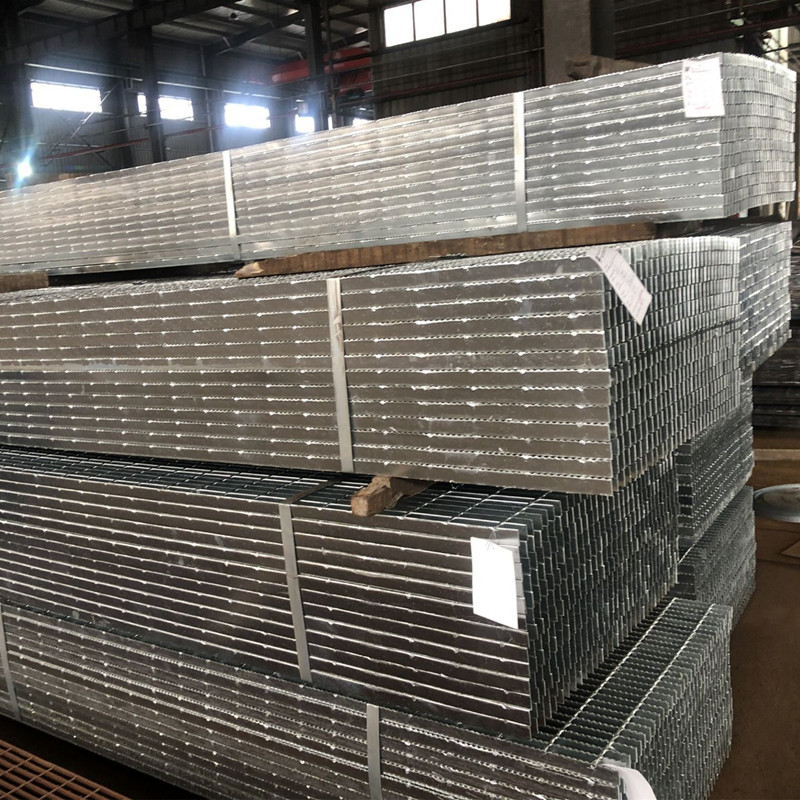

expanded metal mesh thickness

Understanding the intricacies of expanded metal mesh thickness is crucial for industries and projects requiring durable and versatile solutions. As a seasoned expert in material sciences and engineering, I've witnessed firsthand the transformative potential of expanded metal mesh when its thickness is accurately calibrated to specific applications.

Beyond mechanical attributes, one cannot overlook the economical implications of mesh thickness. Thinner meshes might reduce material cost and weight, leading to potential savings. However, they may not possess the durability required for high-stress environments, possibly increasing maintenance or replacement costs over time. Conversely, thicker meshes offer robust resilience but come at a higher initial material cost, making cost-benefit analysis a critical task for procurement specialists. Quality assurance in production of expanded metal mesh is another area where thickness matters. Variations in thickness during production can lead to inconsistencies in performance, which is why manufacturers implement strict quality control procedures. These standards ensure that each sheet of metal can promise uniform performance, reliability, and safety, which are non-negotiable in applications ranging from security to structural. Thus, expanded metal mesh thickness is far from a trivial specification. It is a fundamental property that governs both practical utility and financial efficiency in engineering designs. Selecting the right thickness is a process requiring an in-depth understanding of both material science and the specific demands of the intended application. Being informed and making educated decisions about mesh thickness ensures the mesh performs optimally while achieving project objectives, whether for internal company policy, safety compliance, or maximizing product lifespan. As technology advances and new methods of mesh production are introduced, staying abreast of developments in expanded metal mesh technology will continue to be essential. By doing so, industries can uphold their commitments to safety, innovation, and sustainability, all while delivering projects that meet the rigorous standards of contemporary engineering excellence.

Beyond mechanical attributes, one cannot overlook the economical implications of mesh thickness. Thinner meshes might reduce material cost and weight, leading to potential savings. However, they may not possess the durability required for high-stress environments, possibly increasing maintenance or replacement costs over time. Conversely, thicker meshes offer robust resilience but come at a higher initial material cost, making cost-benefit analysis a critical task for procurement specialists. Quality assurance in production of expanded metal mesh is another area where thickness matters. Variations in thickness during production can lead to inconsistencies in performance, which is why manufacturers implement strict quality control procedures. These standards ensure that each sheet of metal can promise uniform performance, reliability, and safety, which are non-negotiable in applications ranging from security to structural. Thus, expanded metal mesh thickness is far from a trivial specification. It is a fundamental property that governs both practical utility and financial efficiency in engineering designs. Selecting the right thickness is a process requiring an in-depth understanding of both material science and the specific demands of the intended application. Being informed and making educated decisions about mesh thickness ensures the mesh performs optimally while achieving project objectives, whether for internal company policy, safety compliance, or maximizing product lifespan. As technology advances and new methods of mesh production are introduced, staying abreast of developments in expanded metal mesh technology will continue to be essential. By doing so, industries can uphold their commitments to safety, innovation, and sustainability, all while delivering projects that meet the rigorous standards of contemporary engineering excellence.

Share

Latest news

-

Hop Dipped Galvanized /PVC Coated Temporary Fence|Durable Temporary Fencing Solution

NewsJul.13,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fence - XZ Metal|Durable Corrosion Resistance,Easy Installation

NewsJul.13,2025

-

High-Quality Temporary Fencing Solutions - Xuzhou Xingzheng Metal Products | Durable, Modular, Corrosion-Resistant

NewsJul.13,2025

-

Euro Steel Wire Mesh Fence-Durable Security Solution | Xuzhou Metal Technology Co., Ltd.

NewsJul.13,2025

-

Galvanized Iron Wire Anti Insect & Mosquito Mesh Window Screen Net – Xuzhou Metal Products|Durable Pest Control, Corrosion Resistant

NewsJul.13,2025

-

Welded Wire Mesh Panels and Rolls-Durable Industrial Solutions|Custom Fabrication Services

NewsJul.13,2025