Oct . 03, 2025 10:55 Back to list

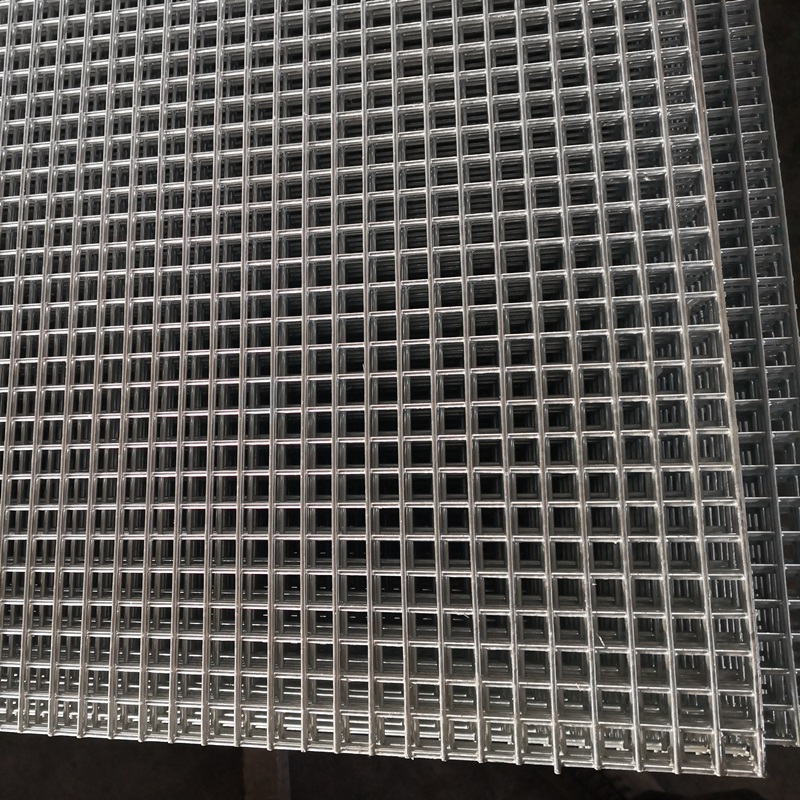

Welded Wire Mesh Panels and Rolls—Galvanized, Custom Sizes?

Field notes from the mesh line: where strength meets speed

If you work with Welded wire mesh panels and rolls, you already know the brief: consistent apertures, dependable welds, finishes that outlast the project warranty. I’ve walked the Anping yards—dusty boots and all—and the operation at 200meters North Of Huangcheng Village, Anping, Hebei, China is, frankly, a classic of the genre: Q195/Q235 wire, bright, tight welds, then finishing to spec.

What’s trending (and what actually matters)

Three currents define today’s mesh: faster panel welding lines with better flatness control; smarter finishing—electro or hot-dip galvanized depending on climate; and, surprisingly, more PVC color requests (olive and RAL7016 are having a moment). Many customers say anti-climb apertures (50×200 mm or tighter) reduce site incidents, which tracks with what I’ve seen on large perimeters.

Process flow (short, honest version)

Welded wire mesh panels and rolls start with low-carbon steel (Q195/Q235). Wire is drawn, straightened, and resistance-welded at the nodes (heat+pressure, no filler). Surfaces then go electro-galvanized for light-duty, hot-dip galvanized (HDG) to ISO 1461 for coastal or industrial zones, or PVC-coated (extrusion or spray) for softer touch and color. Flattening and edge trimming come last. QC checks include weld shear, zinc thickness, aperture tolerance, and adhesion.

Typical lab data (one week in Anping): electro-galv salt-spray ≈240 h, HDG ≈480–720 h, PVC over zinc ≈720–1,000 h per ISO 9227. Real-world service life: around 5–20 years depending on finish, pollution, and maintenance. To be honest, coastal + fertilizer equals tough conditions; choose HDG or PVC over HDG.

Product snapshot

| Parameter | Typical Range (≈) | Notes |

|---|---|---|

| Material | Q195 / Q235 | GB/T 700 grades; low carbon for clean weld nuggets |

| Wire Ø | 1.6–6.0 mm | Heavier gauges for security, lighter for cages |

| Aperture | 12.7×12.7 to 200×200 mm | Custom spacing on request |

| Panel size | 1×2 m to 2.4×3 m | Flatness control ±3 mm/m (around) |

| Rolls | 0.9–1.8 m height; 15–30 m length | Faster installs on long runs |

| Finish | Electro-Galv, HDG, PVC, Paint | ISO 1461 HDG; PVC can be RoHS-compliant |

Applications and advantages

Construction slabs and shotcrete, perimeter and temporary fencing, animal cages and aviaries, welded gabion facings, HVAC guards, machine guarding. The big wins: consistency (tight apertures), rigidity (less sag), and speed—crews love panels that arrive flat. Actually, fewer site welds equals fewer headaches.

Vendor comparison (real-world buying)

| Vendor | Finish Options | Lead Time (≈) | Certification | Note |

|---|---|---|---|---|

| XZ Metal (Anping) | Electro, HDG, PVC, Paint | 10–20 days | ISO 9001 | Custom apertures; strong flatness control |

| Generic Importer | Electro, limited HDG | 30–45 days | Varies | Price-focused; verify weld shear tests |

| Local Fabricator | Paint, some galv | 7–14 days | Shop QA | Quick small runs; check coating thickness |

Customization, testing, and feedback

Custom specs include mesh geometry, wire gauge mix (e.g., heavier horizontals), framed edges, and branded PVC colors. Testing typically references ASTM A185/A185M (weld shear ≥0.75× wire tensile), ISO 1461 (zinc thickness), ISO 9227 (salt spray), and adhesion per ASTM D3359 for painted/PVC finishes. One facilities manager told me, “the HDG panels outlasted the concrete patching on our coastal wall,” which made the accountant smile.

Case notes (short and useful)

- Solar farm fence: 50×200 mm, 4.0 mm wire, PVC over HDG; install time cut ≈18% vs chain-link.

- Precast yard: 6.0 mm panels as rebar alternative in non-structural walls; fewer ties, cleaner finishes.

- Poultry operation: 25×25 mm, 2.0 mm electro-galv rolls; easy cleaning, minimal peck damage reported.

Bottom line: Welded wire mesh panels and rolls deliver reliable geometry and speed on site. Pick the finish to match the environment, ask for the lab sheets, and—this is my recurring mantra—don’t skimp on zinc where salt or chemicals lurk.

Authoritative citations

- ASTM A185/A185M – Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete.

- ISO 1461 – Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

- ISO 9227 – Corrosion tests in artificial atmospheres — Salt spray tests.

- ASTM D3359 – Standard Test Methods for Rating Adhesion by Tape Test.

- GB/T 700 – Carbon structural steels (Q195/Q235 mechanical properties).

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025