- africana

- albanès

- amàric

- àrab

- armeni

- azerbaidjana

- basc

- Bielorús

- bengalí

- bosnià

- búlgar

- català

- Cebuà

- Xina

- Xina (Taiwan)

- Cors

- croat

- txec

- danès

- holandès

- Anglès

- esperanto

- estonià

- finès

- francès

- frisó

- gallec

- georgiana

- alemany

- grec

- Gujarati

- crioll haitiano

- hausa

- hawaià

- hebreu

- No

- Miao

- hongarès

- islandès

- igbo

- indonesi

- irlandesa

- italià

- japonès

- javanès

- Kannada

- kazakh

- Khmer

- Ruandès

- coreà

- kurd

- kirguis

- Treball

- llatí

- letó

- lituà

- luxemburguesa

- macedoni

- Malgashi

- Malai

- malayalam

- maltès

- Maori

- Marathi

- mongol

- Myanmar

- nepalí

- noruec

- noruec

- occità

- Pashto

- persa

- polonès

- portuguès

- panjabi

- romanès

- rus

- samoà

- Gaèlic escocès

- serbi

- Anglès

- Shona

- Sindhi

- Sinhala

- eslovac

- eslovè

- Somali

- espanyol

- Sundanès

- suahili

- suec

- Tagalog

- Tadjik

- Tamil

- tàrtar

- Telugu

- tailandès

- turc

- turcomà

- Ucraïnès

- Urdú

- uigur

- Uzbek

- vietnamita

- gal·lès

- Ajuda

- Yiddish

- ioruba

- Zulu

set. . 08, 2025 14:30 Tornar a la llista

High-Security Single Loop Spiral Razor Barbed Wire Coil (Coin Type)

Introduction to Advanced Perimeter Security Solutions

In an era of heightened security concerns across industrial, commercial, and critical infrastructure sectors, the demand for robust and reliable perimeter defense systems has never been more pressing. Entities spanning petrochemical complexes, military installations, correctional facilities, and vital energy grids require solutions that offer not only physical deterrence but also act as a significant psychological barrier. Among the most effective and widely deployed solutions is the razor barbed wire, an evolution of traditional barbed wire designed for superior security performance.

This article delves into the technical intricacies, application versatility, and operational advantages of the Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda). As a critical component in modern perimeter security, understanding its manufacturing process, material science, and strategic deployment is essential for B2B decision-makers and procurement specialists aiming to optimize their security infrastructure. We will explore industry trends, detailed specifications, real-world applications, and provide insights into vendor selection and customized implementations, ensuring compliance with stringent Google standards for expertise and trustworthiness.

Industry Trends in Perimeter Security and Razor Wire Technology

The global perimeter security market is experiencing sustained growth, driven by increasing geopolitical instability, rising industrial espionage, and the need to protect high-value assets. Key trends include the integration of physical barriers with electronic surveillance (e.g., CCTV, motion sensors), advancements in anti-corrosion materials, and the development of modular, rapidly deployable systems. For instance, the market for physical security systems is projected to reach over $150 billion by 2027, with barrier solutions playing a foundational role. There's a particular emphasis on solutions offering extended service life with minimal maintenance, leading to an increased focus on robust materials and superior coating technologies for products like Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda).

Material Science Advancements

Modern razor wire production emphasizes materials with high tensile strength and exceptional corrosion resistance. Galvanized steel remains the standard, but advanced alloys and multi-layer coating systems (e.g., zinc-aluminum, PVC/powder coating over galvanization) are gaining traction, extending product lifespan significantly in harsh environments such as coastal areas or industrial zones with high chemical exposure. This focus directly impacts the long-term cost of ownership and operational integrity of security fences.

Deployment and Integration

While often installed as a standalone deterrent, contemporary trends see razor wire integrated into comprehensive security frameworks. This involves mounting on top of existing fences, walls, or even ground-level deployments alongside sensor arrays. The modular nature of single-loop coils allows for flexible installation, adapting to varied terrain and existing security architectures, reinforcing the overall security posture without requiring extensive civil engineering work.

Manufacturing Process of Single Loop Spiral Razor Barbed Wire Coil(Coin Type)

The production of Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda) is a meticulous process demanding precision engineering and stringent quality control. It begins with high-grade raw materials and progresses through several automated stages to ensure durability, consistent blade geometry, and optimal security performance.

Raw Material Sourcing and Preparation

- Core Wire: High-carbon steel wire (typically 2.5mm or 2.8mm diameter) with a tensile strength ranging from 1200-1600 MPa (ISO 2235, ASTM A824) is sourced. This wire is critical for structural integrity and resistance to cutting.

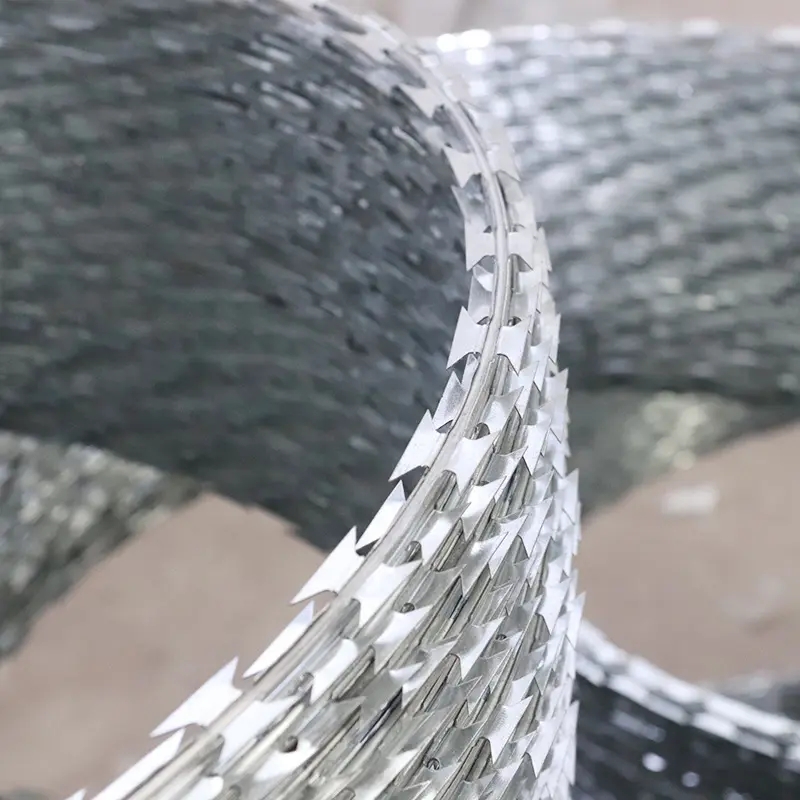

- Razor Blade Material: Galvanized steel strips (typically 0.5mm thickness) conforming to ASTM A653/A653M standards, with a zinc coating weight of 120-275 g/m² per side for superior corrosion resistance. Stainless steel (AISI 304 or 316) is used for specialized applications requiring extreme environmental resilience.

Manufacturing Stages

- Strip Perforation and Shaping (CNC Machining): High-precision CNC machinery stamps and forms the galvanized or stainless steel strips into the distinctive razor barb profiles. This ensures uniformity and sharpness of the blades. The "Coin Type" designation refers to specific blade designs which are typically wider and more aggressive, designed for enhanced deterrence.

- Core Wire Straightening and Feeding: The high-carbon steel wire is uncoiled, straightened, and fed into the assembly line, maintaining precise tension.

- Razor Strip Cold Forming and Crimping: The pre-formed razor strip is then cold-pressed or crimped around the core wire. This process, often automated, ensures a tight, secure attachment of the razor blade to the core wire without welding, preserving the integrity of the galvanization and preventing weak points.

- Coiling (Spiral Formation): The continuous razor wire is fed into a specialized coiling machine that forms it into a single, uniform spiral loop. Unlike cross-concertina wire, single loop coils do not have clips connecting adjacent spirals, offering a simpler, more linear deployment.

- Quality Assurance and Packaging: Each coil undergoes visual inspection for blade consistency, core wire integrity, and coating adherence. Samples are subjected to destructive tests such as tensile strength, zinc coating thickness measurement (ASTM A90/A90M), and salt spray corrosion tests (ASTM B117) to ensure compliance with international standards like ISO 9001 and ANSI specifications. The coils are then securely strapped for transport, often wrapped in moisture-resistant materials.

Service Life and Advantages

Due to the use of highly galvanized or stainless steel, the typical service life of a Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda) ranges from 10 to 25 years, depending on environmental conditions and coating specifications. This extended lifespan translates to significant long-term cost savings in maintenance and replacement. Its primary advantage lies in its superior deterrent capability, energy saving (passive security, no power needed), and exceptional corrosion resistance, making it ideal for target industries such as petrochemical, metallurgy, and water supply & drainage infrastructure where harsh conditions are prevalent.

Technical Specifications and Parameters

Understanding the precise technical parameters of Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda) is crucial for effective procurement and deployment. The following table outlines typical specifications based on industry standards and common product offerings.

Product Specification Table

Comparison with Traditional Barbed Wire

While traditional barbed wire provides a basic deterrent, Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda) offers significantly enhanced security. The following comparison highlights key differences:

Application Scenarios and Technical Advantages

The versatility and effectiveness of Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda) make it suitable for a wide array of high-security applications across various industries.

Target Industries

- Petrochemical Facilities: Refineries, chemical plants, and oil & gas terminals require robust security against sabotage and theft. The corrosion resistance of galvanized or stainless steel razor wire is crucial in these chemically aggressive environments.

- Military and Defense Establishments: Barracks, training grounds, ammunition depots, and border zones rely on razor wire for rapid deployment and formidable deterrence.

- Correctional Facilities: Prisons and detention centers utilize razor wire on perimeter fences and wall tops to prevent escapes.

- Critical Infrastructure: Power stations, water treatment plants, telecommunications hubs, and data centers employ razor wire to protect against vandalism and unauthorized access.

- Mining and Metallurgy Operations: Protecting valuable equipment and materials in remote or harsh industrial settings.

- Water Supply & Drainage Systems: Securing reservoirs, pumping stations, and treatment facilities from contamination or sabotage.

Technical Advantages in Application

- High Deterrent Factor: The sharp, strategically designed "Coin Type" blades present a formidable physical and psychological barrier, significantly increasing the difficulty and risk of unauthorized entry.

- Exceptional Corrosion Resistance: Heavy galvanization (275 g/m²) and optional PVC/powder coatings, or the use of stainless steel, ensure long-term integrity in diverse climatic conditions, including high humidity, coastal salinity, and industrial pollution. This is particularly beneficial for remote sites where maintenance is challenging.

- Low Maintenance Requirements: The inherent durability and corrosion resistance of the materials minimize the need for frequent inspection or repair, leading to lower operational expenditures over the product's lifespan.

- Versatile Deployment: Single loop coils can be rapidly deployed on top of existing fences (chain link, welded mesh), brick walls, concrete barriers, or directly on the ground. They can be installed as linear obstacles or in stacked configurations for enhanced height.

- Cost-Effectiveness: Compared to more complex electronic security systems or extensive guard deployments, razor wire offers a highly effective physical barrier at a relatively low initial investment and minimal ongoing costs. It provides passive security, requiring no power or complex electronic components.

- Durability Against Tampering: The high tensile strength core wire and tightly crimped razor blades make the coil extremely difficult to cut with conventional tools, providing an effective delay mechanism against intruders.

Vendor Comparison and Customized Solutions

Selecting the right vendor for Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda) involves evaluating not just product quality, but also manufacturing capabilities, adherence to international standards, customization options, and after-sales support. A reputable manufacturer will demonstrate transparent processes and verifiable certifications.

Key Vendor Evaluation Criteria

- Certifications: ISO 9001 for quality management, ISO 14001 for environmental management, and OHSAS 18001 for occupational health and safety demonstrate a commitment to best practices. Product-specific certifications (e.g., meeting specific ASTM or EN standards for materials and coatings) are also vital.

- Material Traceability: The ability to trace raw materials back to their origin ensures consistent quality and compliance with specifications.

- Production Capacity: Manufacturers with modern, automated production lines can handle large orders efficiently and maintain consistent quality.

- Experience and Client Portfolio: Years in the industry and a portfolio of satisfied clients, especially in high-security sectors (e.g., government, defense, major industrial firms), lend credibility.

- Technical Support: Availability of engineering support for design, installation guidance, and troubleshooting.

Customized Solutions

While standard coils are widely available, specific projects often necessitate customized solutions. Reputable manufacturers offer flexibility in:

- Coil Diameter and Number of Loops: To achieve specific barrier heights or lengths, tailored coil dimensions can be produced.

- Material Specifications: Beyond standard galvanized steel, options like stainless steel (AISI 304, 316) or heavily galvanized wire with additional PVC/powder coating in specific RAL colors can be provided for extreme environmental conditions or aesthetic integration.

- Blade Profile: While "Coin Type" is a specific design, variations in barb length, width, and spacing can be engineered for specialized security requirements.

- Packaging: Custom packaging solutions, including wooden crates, palletized bundles, or individual wrapping, can facilitate easier handling and transport for diverse project logistics.

Application Case Studies

Case Study 1: Perimeter Upgrade for a Major Petrochemical Plant

A large petrochemical complex in a coastal region faced persistent challenges with perimeter breaches due to its extensive boundary and corrosive environment. Traditional security measures required frequent replacement and lacked adequate deterrence. The solution involved deploying over 15 kilometers of Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda), specified with a high-density zinc-aluminum coating (ZA-275 g/m²) on a 900mm diameter coil, mounted atop existing mesh fences. After 3 years, the site reported a 90% reduction in attempted perimeter breaches, and the razor wire showed no visible signs of corrosion, significantly reducing maintenance costs and enhancing overall site security. The "Coin Type" blade provided the aggressive deterrence needed against determined intruders.

Case Study 2: Rapid Deployment for a Temporary Military Outpost

In a rapidly evolving operational theatre, a military unit required a quick-to-deploy, effective perimeter barrier for a forward operating base. Standard barbed wire was deemed insufficient. Single Loop Spiral Razor Barbed Wire Coils of 600mm diameter were chosen for their ease of transportation and deployment speed. Over 500 meters were installed within 24 hours, creating an immediate, formidable obstacle. The inherent strength and sharp blades of the razor wire provided critical initial deterrence, allowing time for more permanent defenses to be erected. Its simplicity and effectiveness were highlighted in post-mission reviews.

Trustworthiness and Support

Frequently Asked Questions (FAQ)

A1: Single Loop Spiral Razor Barbed Wire Coils are formed into a single spiral and are typically extended to form a linear barrier. Concertina razor wire, while also spiral, consists of two adjacent spirals clipped together at intervals, creating a denser, more volumetric barrier that is harder to penetrate but also heavier and often more complex to deploy.

Q2: What maintenance is required for this type of razor wire?A2: Due to its robust construction and high-quality galvanization or stainless steel material, Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda) requires minimal maintenance. Periodic visual inspections for damage or tampering are recommended, especially after severe weather events. Cleaning is generally not necessary.

Q3: Can these coils be installed by general labor, or is specialized training required?A3: While the installation process is straightforward, due to the sharp nature of the razor blades, specialized training and appropriate personal protective equipment (PPE) are absolutely essential. Professional installation teams are highly recommended to ensure safety and proper deployment.

Lead Time and Fulfillment

Standard orders for Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda) typically have a lead time of 2-4 weeks, depending on quantity and current production schedules. For large-volume or customized orders, lead times may extend to 6-8 weeks. We maintain robust production capabilities and a streamlined logistics network to ensure timely fulfillment. Expedited shipping options are available upon request for urgent requirements.

Warranty Commitments

Our products are backed by comprehensive warranty policies covering manufacturing defects and material integrity. Standard galvanized razor wire typically carries a 5-10 year warranty against premature corrosion, while stainless steel options can extend to 15-20 years. Specific warranty details are provided with each quotation and are dependent on the material specification and environmental conditions of the installation site.

Customer Support

We are committed to providing unparalleled customer support from initial consultation through to post-installation. Our technical sales team is available to assist with product selection, specification clarification, customized design solutions, and installation guidance. For inquiries or support, please visit our contact page or reach out to our dedicated support line during business hours. We also offer on-site technical assistance for large-scale or complex projects.

Conclusion

El Bobina de filferro de pues en espiral d'un sol bucle (tipus de moneda) represents a highly effective, durable, and cost-efficient solution for diverse perimeter security requirements. Its robust construction, superior material science, and ease of deployment make it an indispensable asset for protecting critical infrastructure, industrial facilities, and sensitive areas against unauthorized access. By adhering to international standards and offering flexible customization, manufacturers provide solutions that meet the evolving demands of global security, ensuring peace of mind for B2B clients worldwide.

References

- ASTM International. "Standard Specification for Zinc-Coated (Galvanized) Steel Barbed Wire." ASTM A121/A121M.

- ISO 2235:1992. "Fences and Barriers – Barbed wire – General specification."

- ANSI/ASIS PP.1-2010. "Physical Asset Protection Standard."

- Global Market Insights. "Physical Security Market Size & Share Analysis - Growth Trends & Forecasts (2024 - 2029)."

- Journal of Materials Science. "Corrosion Resistance of Zinc-Aluminum Alloy Coatings on Steel."

-

Durable River Bank Gabion Mesh Solutions for Protection

NotíciesNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

NotíciesNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

NotíciesNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

NotíciesNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

NotíciesNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

NotíciesNov.17,2025