- Afracach

- Albanach

- Amáireach

- Araibis

- Airméinis

- Asarbaiseáinis

- Bascais

- Bealarúisis

- Beangáilis

- Boisnis

- Bulgáiris

- Catalóinis

- Cebuano

- tSín

- An tSín (Taiwan)

- Corsaicis

- Cróitis

- Seiceach

- Danmhairgis

- Ollainnis

- Béarla

- Esperanto

- Eastóinis

- Fionlainnis

- Fraincis

- Freaslainnis

- Gailísis

- Seoirseach

- Gearmáinis

- Gréigis

- Gúisearáitis

- Criól Haiti

- háis

- Haváíais

- Eabhrais

- Ní hea

- Miao

- Ungáiris

- Íoslainnis

- igbo

- Indinéisis

- Gaeilge

- Iodálach

- Seapánach

- Iávais

- Cannadais

- casaicis

- Ciméiris

- Ruanda

- Cóiréis

- Coirdis

- Chirgeastáin

- Saothair

- Laidin

- Laitvis

- Liotuáinis

- Lucsamburgach

- Macadóinis

- Malgashi

- Malaeis

- Mailéalaimis

- Máltais

- Maorais

- Marathi

- Mongóilis

- Maenmar

- Neipealais

- Ioruais

- Ioruais

- Occitan

- Paistis

- Peirsis

- Polainnis

- Portaingéilis

- Puinseáibis

- Rómáinis

- Rúisis

- Samóis

- Gaeilge na hAlban

- Seirbis

- Béarla

- Shona

- Sindhi

- Siolóinis

- Slóvaicis

- Slóivéinis

- Somáilis

- Spainnis

- Sundais

- Svahaílis

- Sualainnis

- Tagálaigis

- Táidsíc

- Tamailis

- Tatairis

- Teileagúis

- Téalainnis

- Tuircis

- Tuircméinis

- Úcráinis

- Urdais

- Uighur

- Úisbéicis

- Vítneaimis

- Breatnais

- Cabhrú

- Giúdais

- Iarúibis

- Súlúis

Oct . 20, 2025 12:03 Ar ais chuig an liosta

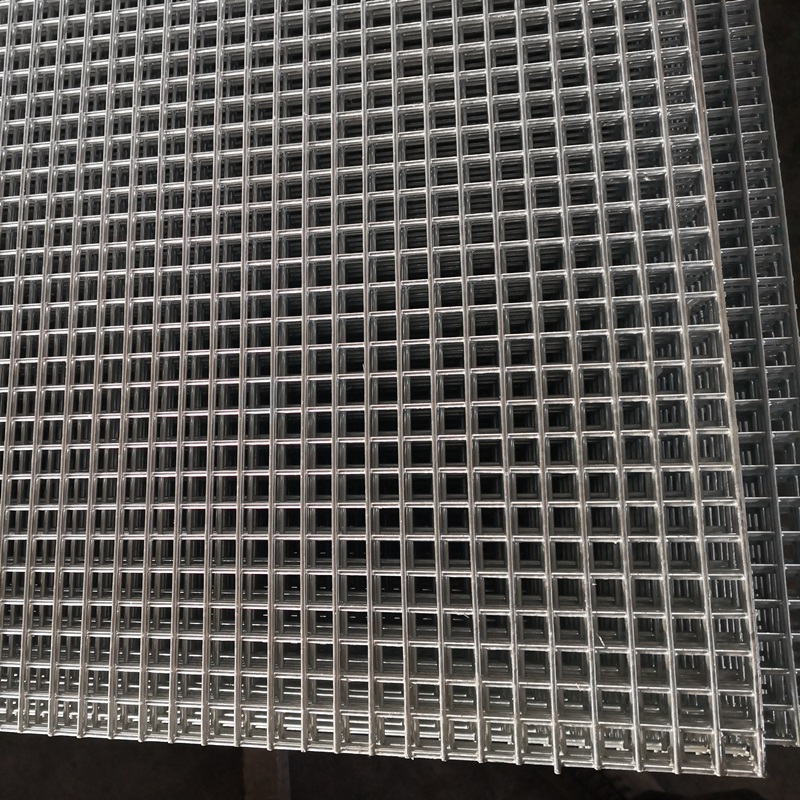

Welded Wire Mesh Panels and Rolls – Durable, Custom Sizes

Painéil agus rollaí mogalra sreinge táthaithe is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire ropes and their products. This article explores how Anping County Xingzhi Metal Wiremesh Products Co.,Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Welded wire mesh panels and rolls Overview

- Benefits & Use Cases of Welded wire mesh panels and rolls in Manufacturing of metal wire ropes and their products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Welded wire mesh panels and rolls from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

Welded wire mesh panels and rolls Overview

Welded wire mesh panels and rolls are precision-joined grids of low-carbon steel, galvanized steel, or stainless steel wires, resistance-welded at every intersection for uniform strength and flatness. In fabricated metal products and wire-rope-related manufacturing, they serve as structural guards, partitions, machine enclosures, storage decking, and process baskets where dimensional accuracy, open-area visibility, and airflow are critical. Typical specifications include mesh openings from 6×6 mm to 200×200 mm, wire diameters from 1.2–8.0 mm, roll widths up to 2.4 m, roll lengths up to 30 m, and panel formats like 1×2 m, 1.2×2.4 m, or custom sizes. Surface options commonly include electro-galvanized, hot-dip galvanized, PVC-coated, and 304/316 stainless to match different corrosion environments.

Anping County Xingzhi Metal Wiremesh Products Co.,Ltd manufactures welded wire mesh with automated multi-point resistance welding for consistent weld integrity and tight tolerances. Flatness and squareness are controlled through in-line leveling, while optional edge trimming and framing simplify installation. For B2B buyers in high-throughput plants, these attributes translate into faster commissioning, safer operations, and lower lifetime maintenance.

Benefits & Use Cases of Welded wire mesh panels and rolls in Manufacturing of metal wire ropes and their products

In wire rope production lines—stranding, cabling, closing, and spooling—welded wire mesh panels and rolls are widely used for perimeter guarding, moving-part enclosures, and safety partitions that maintain visibility while meeting protection needs. Rolls enable rapid coverage of long runs (conveyors, walkways, or storage aisles), while rigid panels provide precise, durable frames for machine cells, pay-off/ take-up areas, and access-controlled cages. The consistent aperture size supports reliable ventilation and inspection, and corrosion-resistant coatings withstand lubricant mist, drawing compounds, and periodic washdowns common in wire rope plants.

Additional applications include pallet rack decking for drum and spool storage, wire-mesh bins and baskets for heat-treatment or phosphating lines, and sorting screens in QC and finishing. Competitive advantages include high strength-to-weight ratio, excellent dimensional consistency, easy cutting/fastening, and compatibility with standard clamps, U-channels, and posts. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd’s engineering support helps B2B teams select the right mesh size, wire gauge, and coating for the specific load, airflow, and corrosion profile—reducing rework and improving safety compliance.

Cost, Maintenance & User Experience

Total cost of ownership for welded wire mesh panels and rolls is driven by installation speed, service life, and minimal upkeep. Pre-flattened panels reduce on-site adjustment, while rolls cut labor on long runs. Hot-dip galvanized and stainless options extend service life in humid or chemical environments, limiting repaint cycles and downtime. For many users, the ROI comes from fewer maintenance stops, safer line access, and long-term corrosion resistance—especially when mesh serves as both protective guard and visual inspection window.

Customers in the fabricated metal products sector often report smoother installs due to consistent panel squareness and stable welds that resist deformation during fastening. Routine maintenance is straightforward: periodic wipe-downs, inspection of fasteners, and touch-up of cut edges on galvanized mesh. When specified correctly, typical service spans several years in indoor environments and multiple seasons outdoors, even with exposure to lubricants and cleaning agents. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd supports lifecycle value with customizable packaging, clear labeling, and replenishment programs that keep spares aligned to plant standards.

Sustainability & Market Trends in manufacturing

Welded wire mesh panels and rolls align with manufacturers’ sustainability goals through recyclability and resource efficiency. Steel mesh is 100% recyclable, and durable zinc or stainless finishes reduce paint use and solvent emissions over time. Process optimizations—like precise wire drawing and automated welding—help minimize scrap and energy per square meter of mesh produced. As factories aim for leaner, safer, and more transparent operations, modular mesh guarding and decking support changes in layout without major material waste.

Market trends show increasing demand for machine safety, standardized guarding kits, and rapid deployment solutions that complement automation upgrades. Additionally, buyers prioritize traceability and consistent quality across global sites. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd is investing in process control and material options to meet these expectations, offering meshes tailored to corrosive environments, high-visibility zones, and heavy-duty storage. The result is a future-ready solution set that balances safety, efficiency, and environmental responsibility in modern metalworking and wire rope manufacturing plants.

Conclusion on Welded wire mesh panels and rolls from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

For B2B decision makers in fabricated metal products and wire rope manufacturing, welded wire mesh panels and rolls deliver reliable safety, airflow, visibility, and structural performance. With versatile specs, long-lasting coatings, and installation-friendly formats, they drive measurable uptime and lifecycle value. Backed by Anping County Xingzhi Metal Wiremesh Products Co.,Ltd’s manufacturing expertise and responsive service, your team can specify confidently and implement quickly.

Contact us: email: sales2@xzmetal.com

Visit our website: https://www.xzmetal.com

-

Durable River Bank Gabion Mesh Solutions for Protection

NuachtNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

NuachtNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

NuachtNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

NuachtNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

NuachtNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

NuachtNov.17,2025