Welcome to our websites!

ஜன . 26, 2025 07:12 Back to list

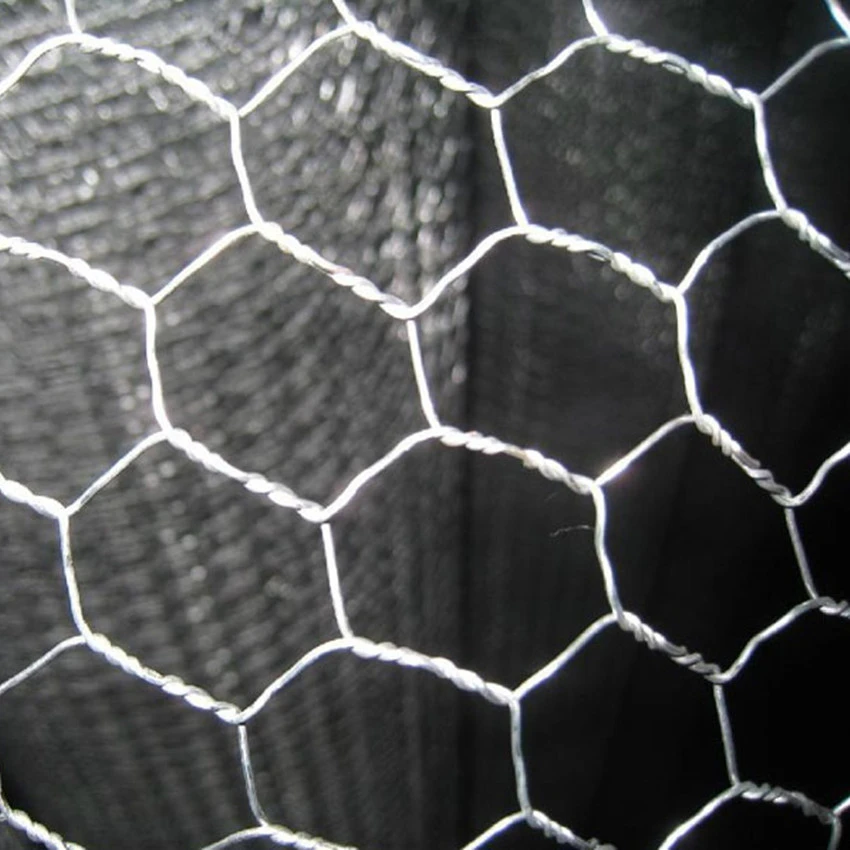

reinforcement wire mesh panels

Reinforcement wire mesh panels have become essential components in construction and infrastructure projects around the globe. This article dives into the nuances of these panels by exploring their practical applications, understanding their engineering marvels, and establishing a connection between theoretical expertise and real-world utility.

The production of these panels involves intricate processes that guarantee their quality and performance. Expert manufacturers follow stringent guidelines and standards to ensure that the wire mesh panels can endure significant loads and environmental challenges. This adherence to quality control and industry standards imbues trust among contractors and developers who rely on these products daily. Real-world experiences highlight the versatility and necessity of reinforcement wire mesh panels. A construction case study involving a large metropolitan development illustrated the practicality of these panels in a fast-paced urban environment. Builders noted that the reduced need for traditional rebar tying significantly expedited the project timeline. Additionally, the uniformity of load distribution achieved with these panels led to reductions in material usage without compromising structural integrity. Moreover, these panels are gaining traction in the green building movement. Certain manufacturers now offer eco-friendly versions made from recycled steel, aligning with responsible building practices and reducing the carbon footprint of construction activities. This sustainable approach resonates with developers committed to environmentally conscious projects, thus broadening the appeal and application of reinforcement wire mesh panels. Trustworthiness in this domain not only stems from rigorous testing and proven efficacy but also from the shared experiences of industry experts who have seen first-hand the invaluable role these panels play. Testimonials from leading construction firms position reinforcement wire mesh panels as indispensable tools. These endorsements from within the industry lend credibility and validate their use across diverse architectures and infrastructures. In conclusion, reinforcement wire mesh panels stand as a testament to the convergence of engineering excellence and practical utility. They underscore the importance of embracing technology and materials that offer not just theoretical benefits but tangible, real-world results. As construction needs evolve, these panels remain pivotal in delivering safe, efficient, and sustainable solutions that meet the demands of modern infrastructure. Their ongoing development and adaptation to new construction paradigms ensure that they will remain at the forefront of innovative building practices for years to come.

The production of these panels involves intricate processes that guarantee their quality and performance. Expert manufacturers follow stringent guidelines and standards to ensure that the wire mesh panels can endure significant loads and environmental challenges. This adherence to quality control and industry standards imbues trust among contractors and developers who rely on these products daily. Real-world experiences highlight the versatility and necessity of reinforcement wire mesh panels. A construction case study involving a large metropolitan development illustrated the practicality of these panels in a fast-paced urban environment. Builders noted that the reduced need for traditional rebar tying significantly expedited the project timeline. Additionally, the uniformity of load distribution achieved with these panels led to reductions in material usage without compromising structural integrity. Moreover, these panels are gaining traction in the green building movement. Certain manufacturers now offer eco-friendly versions made from recycled steel, aligning with responsible building practices and reducing the carbon footprint of construction activities. This sustainable approach resonates with developers committed to environmentally conscious projects, thus broadening the appeal and application of reinforcement wire mesh panels. Trustworthiness in this domain not only stems from rigorous testing and proven efficacy but also from the shared experiences of industry experts who have seen first-hand the invaluable role these panels play. Testimonials from leading construction firms position reinforcement wire mesh panels as indispensable tools. These endorsements from within the industry lend credibility and validate their use across diverse architectures and infrastructures. In conclusion, reinforcement wire mesh panels stand as a testament to the convergence of engineering excellence and practical utility. They underscore the importance of embracing technology and materials that offer not just theoretical benefits but tangible, real-world results. As construction needs evolve, these panels remain pivotal in delivering safe, efficient, and sustainable solutions that meet the demands of modern infrastructure. Their ongoing development and adaptation to new construction paradigms ensure that they will remain at the forefront of innovative building practices for years to come.

Share

Latest news

-

Galvanized Welded Wire Mesh Gabion Box/Basket | Durable and Eco-Friendly Solutions for Civil Engineering and Landscaping

NewsJul.12,2025

-

Backyard Temporary Fence – Easy Install & Removable Fencing Solutions for Home Safety

NewsJul.08,2025

-

High-Quality Temporary Chain Link Fencing Supplier Factory Direct Price

NewsJul.08,2025

-

High Quality 9 Gauge Expanded Metal Mesh - Durable Chain Link Wire Mesh Fence Solutions

NewsJul.07,2025

-

High-Quality Farm Fence Netting for Sale Competitive Quotes & Pricelist Trusted Exporters

NewsJul.07,2025

-

Welded Wire Fencing 4x4 Mesh – Durable & Versatile Security Solution

NewsJul.06,2025