Iyul . 12, 2025 03:54 Back to list

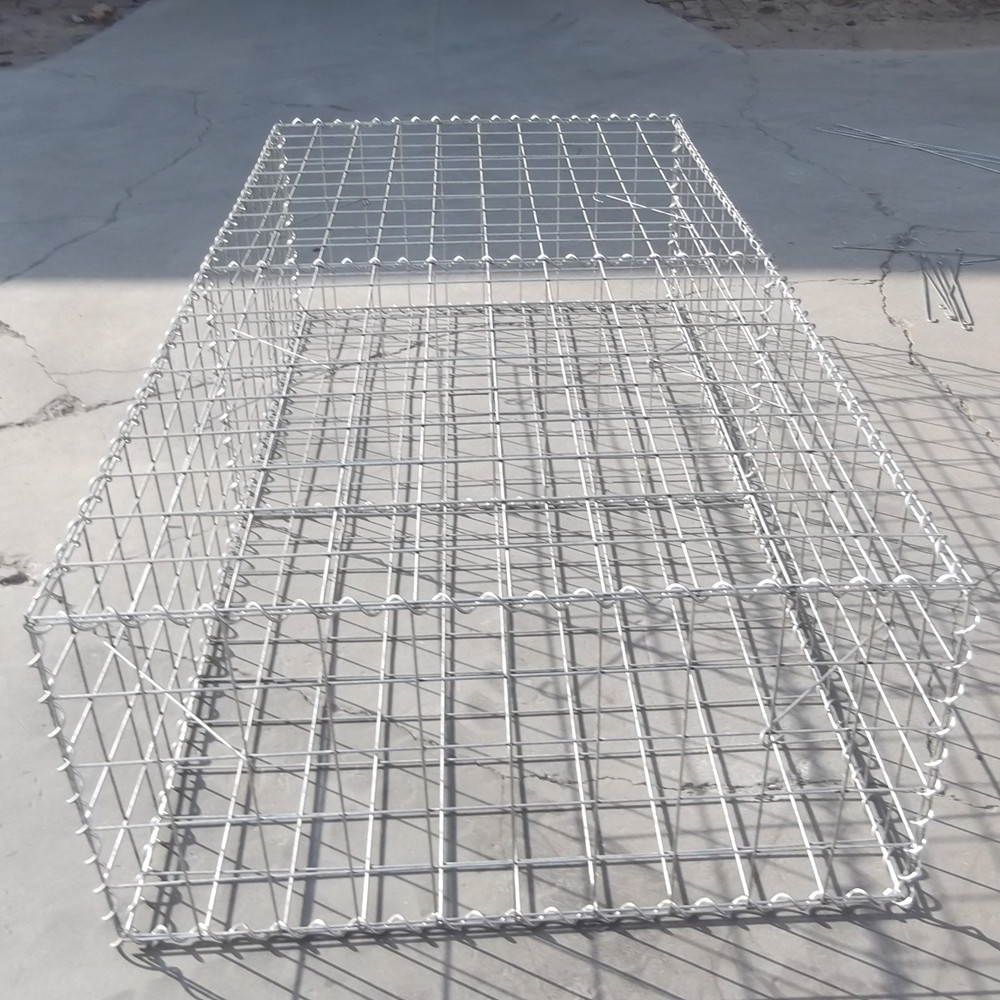

Galvanized Welded Wire Mesh Gabion Box/Basket | Durable and Eco-Friendly Solutions for Civil Engineering and Landscaping

Galvanized Welded Wire Mesh Gabion Box/Basket | Durable and Eco-Friendly Solutions for Civil Engineering and Landscaping

Galvanized welded wire mesh gabion boxes and baskets have become essential components in modern civil engineering and landscaping projects. These structures, made from corrosion-resistant galvanized steel wire, offer a versatile and sustainable solution for erosion control, slope stabilization, and decorative applications. Whether you're working on a large-scale infrastructure project or a small garden design, gabion boxes provide the strength and flexibility needed to meet diverse requirements. This comprehensive guide explores the features, benefits, technical specifications, and applications of galvanized welded wire mesh gabion boxes, along with insights into the company behind this innovative product: Xinzhong Metal Co., Ltd.

Product Overview: What is a Galvanized Welded Wire Mesh Gabion Box/Basket?

A galvanized welded wire mesh gabion box or basket is a modular, wire-mesh structure designed to be filled with stones, gravel, or other materials. The term "gabion" originates from the Italian word for "cage," reflecting its function as a containment system. These boxes are constructed using high-quality galvanized steel wire, which undergoes a hot-dip galvanization process to enhance durability and resistance to rust. The welded mesh design ensures structural integrity, making gabion boxes ideal for both functional and aesthetic applications.

One of the key advantages of gabion boxes is their adaptability. They can be customized to fit various shapes and sizes, allowing for creative design solutions. The open structure of the wire mesh promotes natural drainage, reducing the risk of water buildup and soil erosion. Additionally, the flexibility of the mesh allows the boxes to conform to uneven terrain, ensuring a stable foundation even in challenging environments.

Technical Specifications and Material Composition

The performance of galvanized welded wire mesh gabion boxes is largely determined by their material composition and construction. Here are the key technical specifications:

- Material: High-strength galvanized steel wire, typically with a zinc coating of 275 g/m² or higher for enhanced corrosion resistance.

- Wire Diameter: Ranges from 2.5mm to 4mm, depending on the application and load requirements.

- Mesh Size: Common options include 50x50mm, 60x60mm, and 100x100mm, offering varying levels of flexibility and strength.

- Galvanization Process: Hot-dip galvanization ensures a uniform zinc coating, protecting the wire from rust and extending the product's lifespan.

- Dimensions: Standard sizes include 1m x 1m x 0.5m, 2m x 1m x 0.5m, and custom dimensions to suit specific project needs.

- Standards: Compliant with international standards such as ISO 9001 and ASTM A649 for quality and performance.

The galvanized steel wire used in these boxes is chosen for its exceptional tensile strength and resistance to environmental factors. The hot-dip galvanization process involves immersing the wire in molten zinc, creating a protective layer that prevents oxidation. This makes gabion boxes suitable for both short-term and long-term projects, even in harsh climates.

Applications of Galvanized Welded Wire Mesh Gabion Boxes

Galvanized welded wire mesh gabion boxes are widely used across multiple industries due to their versatility and durability. Below are some of the most common applications:

1. Erosion Control and Riverbank Protection

One of the primary uses of gabion boxes is in erosion control, particularly along riverbanks, coastlines, and slopes. When filled with stones, the boxes act as a barrier against water flow, reducing soil erosion and protecting the surrounding environment. The permeable structure of the mesh allows water to pass through while retaining the fill material, preventing sedimentation and maintaining the natural ecosystem.

2. Slope Stabilization and Retaining Walls

Gabion boxes are commonly used to stabilize slopes and construct retaining walls. By filling the boxes with rocks or concrete, engineers can create a stable structure that resists soil movement. The flexibility of the mesh allows the boxes to adjust to ground shifts, reducing the risk of cracks or failures. This makes them ideal for road construction, railway embankments, and hillside developments.

3. Urban Landscaping and Decorative Features

In addition to functional applications, gabion boxes are popular in urban landscaping for their aesthetic appeal. They can be used to create retaining walls, garden borders, and even decorative elements in public spaces. The natural look of the filled boxes blends seamlessly with the environment, offering a sustainable alternative to concrete or stone structures.

4. Flood Defense and Coastal Protection

Coastal areas and flood-prone regions benefit from gabion boxes as part of their flood defense systems. When placed along shorelines or in flood channels, the boxes absorb and redirect water flow, minimizing damage from storms or high tides. Their durability ensures long-term protection against environmental challenges.

Why Choose Galvanized Welded Wire Mesh Gabion Boxes?

The popularity of galvanized welded wire mesh gabion boxes stems from their numerous advantages. Here are some key reasons to consider this solution:

1. Exceptional Durability

The galvanized steel wire used in these boxes is designed to withstand harsh weather conditions and heavy loads. The zinc coating prevents rust, ensuring a lifespan of 30 years or more in most environments. This longevity makes gabion boxes a cost-effective investment compared to traditional materials like concrete.

2. Cost-Effective and Sustainable

Gabion boxes are relatively inexpensive to produce and install, especially when compared to concrete or steel structures. Their modular design allows for quick assembly, reducing labor costs. Additionally, the use of locally sourced stones or recycled materials minimizes the environmental impact, aligning with sustainable construction practices.

3. Environmental Friendliness

Unlike concrete, which requires significant energy to produce and emits carbon dioxide, gabion boxes are eco-friendly. The open structure of the mesh promotes biodiversity by allowing plants to grow through the gaps, creating a natural habitat for insects and small animals. This makes them an ideal choice for green infrastructure projects.

4. Easy Installation and Maintenance

Gabion boxes are easy to install, even for DIY enthusiasts. The modular design allows for straightforward assembly, and the lightweight nature of the boxes simplifies transportation. Maintenance is minimal, requiring only occasional inspections to ensure the fill material remains intact and the structure is secure.

5. Versatile Design Options

With customizable dimensions and mesh sizes, gabion boxes can be tailored to fit specific project requirements. They are available in a range of colors and finishes to match different architectural styles, making them suitable for both industrial and residential applications.

Company Background: Xinzhong Metal Co., Ltd.

Xinzhong Metal Co., Ltd. is a leading manufacturer of galvanized welded wire mesh gabion boxes and baskets, with over two decades of experience in the metal products industry. Established in 2003, the company has built a reputation for delivering high-quality, durable solutions that meet the evolving needs of civil engineering and landscaping projects.

As a certified ISO 9001 company, Xinzhong Metal adheres to strict quality control standards, ensuring that every product meets international benchmarks. The company's commitment to innovation and customer satisfaction has earned it a loyal clientele across the globe. From small-scale projects to large infrastructure developments, Xinzhong Metal provides reliable, cost-effective solutions that stand the test of time.

Visit Xinzhong Metal Co., Ltd. to learn more about their products and services.

Case Studies: Real-World Applications of Galvanized Welded Wire Mesh Gabion Boxes

Several successful projects highlight the effectiveness of galvanized welded wire mesh gabion boxes in diverse environments:

1. Riverbank Protection in the Yangtze River Basin

In a recent project along the Yangtze River, gabion boxes were used to stabilize eroding banks and prevent sedimentation. The boxes, filled with locally sourced stones, created a natural barrier that reduced water flow and protected the surrounding ecosystem. The project was completed within six months, demonstrating the efficiency of gabion boxes in large-scale environmental restoration.

2. Urban Retaining Walls in Shanghai

Shanghai's urban development required the construction of retaining walls to support new residential areas. Gabion boxes were chosen for their durability and aesthetic appeal. The boxes were filled with decorative stones and integrated into the landscape, creating a seamless blend of functionality and beauty. The project received positive feedback for its sustainable approach to urban planning.

3. Coastal Flood Defense in Guangdong

Coastal regions in Guangdong faced frequent flooding due to rising sea levels. Xinzhong Metal's gabion boxes were deployed as part of a flood defense system, installed along the shoreline to absorb wave energy. The boxes' permeable design allowed water to pass through while retaining the fill material, effectively reducing the impact of storms on the coastline.

Installation and Maintenance Guide

Proper installation and maintenance are crucial to maximizing the lifespan and performance of galvanized welded wire mesh gabion boxes. Here's a step-by-step guide:

1. Site Preparation

Before installing the boxes, the site must be cleared of debris and leveled. A compacted gravel base is recommended to ensure stability, especially for large-scale projects.

2. Assembly of the Boxes

The gabion boxes are typically pre-fabricated and delivered to the site. They can be assembled by connecting the mesh panels with wire ties or clips. For larger boxes, a frame may be required to maintain structural integrity during filling.

3. Filling the Boxes

The boxes are filled with stones, gravel, or other suitable materials. The fill should be compacted in layers to prevent settling. For slope stabilization, the fill material should be chosen based on the soil type and load-bearing requirements.

4. Securing the Boxes

Once filled, the boxes are secured with additional wire ties or anchor points to prevent displacement. For retaining walls, the boxes are stacked and interconnected to create a cohesive structure.

5. Maintenance

Regular inspections are recommended to check for signs of wear or damage. Any loose wires or gaps in the mesh should be repaired promptly. The fill material should be replenished if necessary to maintain the box's stability.

Comparison with Alternative Solutions

While there are several alternatives to gabion boxes, such as concrete retaining walls and timber structures, gabion boxes offer distinct advantages:

- Cost-Effectiveness: Gabion boxes are generally more affordable than concrete, especially for large projects. The lightweight design reduces transportation and labor costs.

- Sustainability: Unlike concrete, which has a high carbon footprint, gabion boxes use natural materials and promote biodiversity.

- Flexibility: The modular design of gabion boxes allows for easy adjustments, whereas concrete structures are rigid and difficult to modify.

- Aesthetic Appeal: Gabion boxes blend seamlessly with natural environments, making them ideal for landscaping and urban projects.

FAQ: Frequently Asked Questions

Q1: How long do galvanized welded wire mesh gabion boxes last?

A: With proper installation and maintenance, these boxes can last 30 years or more, depending on environmental conditions.

Q2: Can gabion boxes be customized for specific projects?

A: Yes, Xinzhong Metal offers custom dimensions and mesh sizes to suit unique project requirements.

Q3: Are gabion boxes environmentally friendly?

A: Yes, they are made from recyclable materials and promote ecological balance by allowing plant growth.

Q4: What is the typical weight of a gabion box?

A: The weight varies based on the size and fill material, but a standard 1m x 1m x 0.5m box filled with stones weighs approximately 150-200 kg.

Q5: How do I install gabion boxes?

A: Installation involves site preparation, assembling the mesh, filling with stones, and securing the structure. Detailed instructions are available on the product page.

Conclusion: Invest in Reliable and Sustainable Solutions

Galvanized welded wire mesh gabion boxes are a versatile, durable, and environmentally friendly choice for a wide range of applications. Whether you're working on erosion control, slope stabilization, or urban landscaping, these boxes provide a cost-effective solution that stands the test of time. With Xinzhong Metal Co., Ltd.'s commitment to quality and innovation, you can trust in the performance of their products. Visit Xinzhong Metal Co., Ltd. to explore their range of gabion boxes and baskets, or contact them directly for custom quotes and technical support.

Learn more about our galvanized welded wire mesh gabion boxes and baskets.

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Zhejiang Metal Co., Ltd.|Durable Temporary Fencing&Weather-Resistant Solution

NewsJul.12,2025

-

Galvanized Welded Wire Mesh Gabion Box/Basket | Durable and Eco-Friendly Solutions for Civil Engineering and Landscaping

NewsJul.12,2025

-

Backyard Temporary Fence – Easy Install & Removable Fencing Solutions for Home Safety

NewsJul.08,2025

-

High-Quality Temporary Chain Link Fencing Supplier Factory Direct Price

NewsJul.08,2025

-

High Quality 9 Gauge Expanded Metal Mesh - Durable Chain Link Wire Mesh Fence Solutions

NewsJul.07,2025

-

High-Quality Farm Fence Netting for Sale Competitive Quotes & Pricelist Trusted Exporters

NewsJul.07,2025