- afrikalik

- alban

- Amhar

- arabcha

- arman

- ozarbayjon

- bask

- belarus

- bengal

- bosniyalik

- bolgar

- katalan

- Sebuano

- Xitoy

- Xitoy (Tayvan)

- Korsika

- xorvat

- chex

- Daniya

- golland

- Ingliz

- Esperanto

- eston

- fin

- frantsuz

- frizcha

- Galisian

- gruzin

- nemis

- yunoncha

- Gujarati

- Gaiti kreoli

- hausa

- gavayilik

- ibroniy

- yoq

- Miao

- venger

- island

- igbo

- indonez

- irland

- italyancha

- yapon

- yava

- Kannada

- qozoq

- kxmer

- Ruanda

- koreys

- kurd

- qirg'iz

- Mehnat

- lotin

- latviyalik

- litva

- Lyuksemburg

- makedon

- Malgashi

- malay

- Malayalam

- malta

- maori

- marati

- mo'g'ul

- Myanma

- Nepal

- norveg

- norveg

- oksitan

- Pushtu

- forscha

- polyak

- portugal

- panjob

- rumin

- rus

- Samoa

- Shotlandiya gael tili

- serb

- Ingliz

- Shona

- Sindhi

- Sinhala

- slovak

- sloven

- Somali

- ispancha

- sundan

- suahili

- shvedcha

- Tagalog

- tojik

- Tamil

- tatar

- Telugu

- tay

- turkcha

- turkman

- ukrain

- urdu

- uyg'ur

- o'zbek

- Vetnam

- uels

- Yordam

- Yahudiy

- Yoruba

- Zulu

Okt . 13, 2025 12:46 Roʻyxatga qaytish

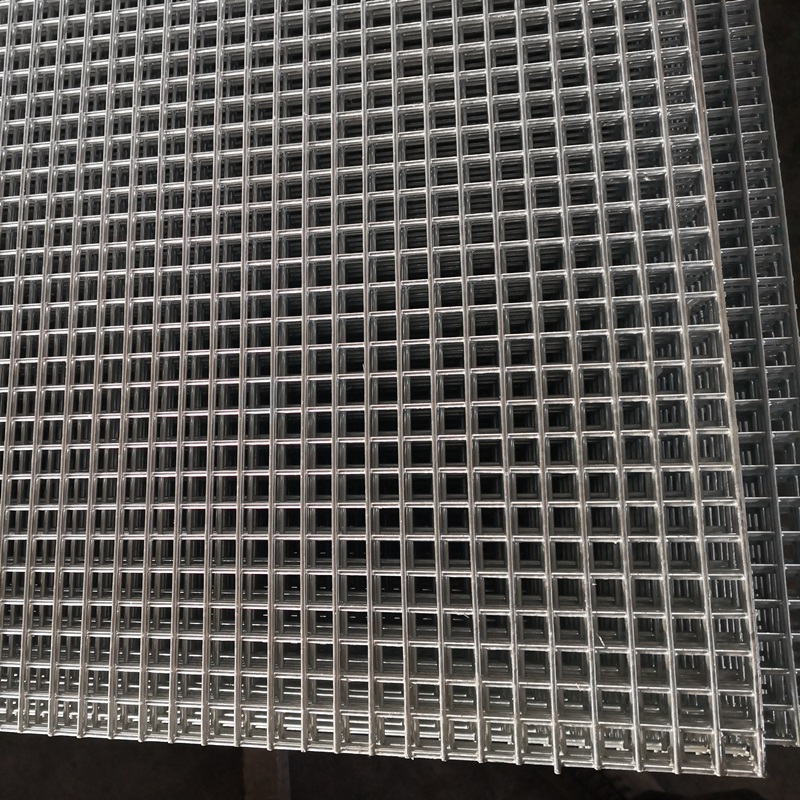

Welded Wire Mesh Panels and Rolls—Galvanized, Custom—Why Us?

A Field Guide to Welded Mesh: What Pros Actually Buy and Why

If you spend time on job sites or farm roads around Anping, you hear it constantly: Payvandlangan tel to'r panellari va rulolar keep projects moving. From the production lines north of Huangcheng Village in Anping, Hebei, to coastal warehouses, this category has quietly become the backbone for fencing, cages, formwork, and even gabion skins. And yes, I’ve seen more than a few crews switch after a single trial lot—usually for the weld consistency.

What’s trending (and why it matters)

Demand has shifted toward hot-dip galvanized and PVC-coated meshes for longer service life, especially where maintenance budgets are tight. Contractors tell me they prefer pre-fabricated panels for speed, but still keep rolls on hand for long runs and terrain that isn’t exactly forgiving. Honestly, it’s a practicality story: fewer posts, fewer cuts, fewer headaches.

Materials, process, and testing (the real nuts and bolts)

- Base steel: Q195 or Q235 low-carbon wire (typical tensile ≈ 350–550 MPa).

- Welding: Automatic resistance welding; heat-balanced to minimize HAZ brittleness.

- Surfaces: Electro-galvanized, hot-dip galvanized (post-weld), PVC coated, or industrial painting.

- QA checks: Weld shear tests (sample-based), aperture tolerance checks, zinc mass/thickness measurement, coating adhesion, and accelerated corrosion.

- Typical standards referenced: ASTM A641 (zinc-coated wire), ASTM A1064 (welded wire), ISO 1461 (HDG), EN 10244-2 (wire coatings), ASTM B117 (salt spray), ASTM D3359 (adhesion), ISO 4892 (UV aging).

Service life (inland, real-world use may vary): electro-galv ≈ 2–5 yrs; hot-dip ≈ 10–25 yrs; PVC-coated ≈ 8–20 yrs; painted ≈ 3–7 yrs. Coastal or chemical exposure will shorten that—no surprises there.

Specification snapshot

| Material | Q195 / Q235 |

| Tel diametri | ≈ 1.0–6.0 mm |

| Mesh opening | 12.7×12.7 mm to 100×100 mm (others on request) |

| Panelning o'lchami | ≈ 0.9×2.4 m to 2.4×3.0 m |

| Roll size | Height 0.9/1.2/1.5/1.8 m; length 25–30 m |

| Coatings | Electro-Galv (8–15 µm), HDG (≈40–85 µm), PVC, Paint |

| Typical tests | Salt spray 96–480 h; adhesion 4B–5B; weld shear ≥ 600 N (sample) |

Where it’s used (and what users say)

- Construction: temporary fencing, plaster/stucco backing, slab-on-grade reinforcement (light-duty).

- Agriculture: animal cages, poultry runs, orchard fencing.

- Infrastructure: gabion facings, slope protection, equipment guards.

Feedback? Many customers say install time drops by a third when switching to panels. It seems that PVC-coated mesh survives coastal drizzle better than paint—unsurprising but worth noting. And yes, Payvandlangan tel to'r panellari va rulolar ship well nested; that matters when freight costs bite.

Quick vendor comparison

| Vendor | Coating options | Lead time | Customization | Certs | Notes |

|---|---|---|---|---|---|

| XZ Metal (Anping) | Electro, HDG, PVC, Paint | 7–15 days | Aperture, wire Ø, panel size | ISO 9001 | Origin: 200 m N of Huangcheng Village, Hebei |

| Vendor A (Domestic) | Electro, HDG | 10–20 days | Limited | Factory QA only | Budget-focused |

| Vendor B (Import) | HDG, PVC | 25–40 days | Diafragma | ISO 9001 | Good for bulk only |

Real projects (short and sweet)

- Logistics park fence, inland China: HDG panels cut install time by ≈30%; zero red rust at 18 months.

- Poultry farm, humid delta: PVC-coated rolls reduced injuries to birds; easy hose-down cleanup.

- Drainage slope revetment: mesh plus rock fill held up through two rainy seasons; minor touch-ups only.

Final note: if you need odd apertures or mixed panels-and-rolls in one shipment, Payvandlangan tel to'r panellari va rulolar from a plant that runs both coating lines and welding under one roof is, in my experience, the sanity-saving option.

Authoritative citations

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire. astm.org

- ASTM A1064/A1064M – Steel Wire and Welded Wire Reinforcement. astm.org

- ISO 1461 – Hot dip galvanized coatings on fabricated iron and steel articles. iso.org

- EN 10244-2 – Steel wire and wire products: Zinc or zinc alloy coatings. cen.eu

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus. astm.org

- ASTM D3359 – Measuring Adhesion by Tape Test. astm.org

- ISO 4892 – Plastics: Methods of exposure to laboratory light sources. iso.org

-

Durable River Bank Gabion Mesh Solutions for Protection

YangiliklarNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

YangiliklarNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

YangiliklarNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

YangiliklarNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

YangiliklarNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

YangiliklarNov.17,2025